Hi bz,

For what it's worth...

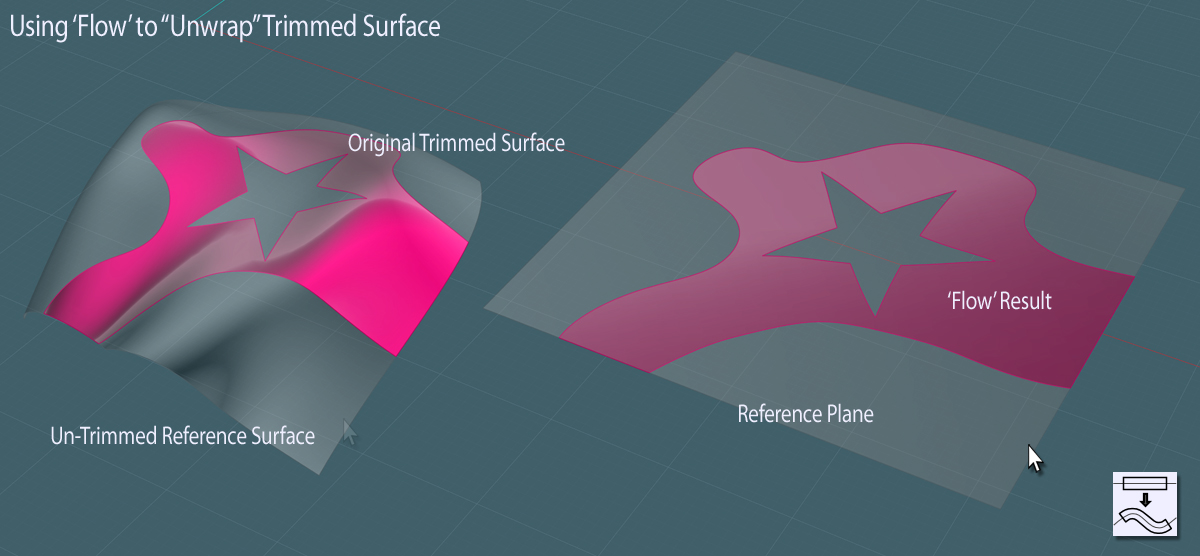

As far as "approaches," one can be to use MoI's Flow feature, though I can't guarantee complete accuracy or success every time.

Basically, this can only be done with a single-surface object, but it can allow you to work with the trimming curve detail and apply new detail by reversing the process.

Sorry, but I can't really show a good tutorial for this, since I'm not sure it works all the time, especially on surfaces expressed with only three corners.

1) Make sure the desired surface is separated and standing by itself. This will make it easier to work with.

Copy the surface and paste it in place.

2) Do the "Untrimming" script:

code:

script: /* Untrim the selected surface */ var gd = moi.geometryDatabase; srfs = gd.getSelectedObjects().getSingleFaceBReps(); gd.deselectAll(); for ( var i = 0; i < srfs.length; ++i ) srfs.item(i).getEdges().setProperty( 'selected', true ); moi.command.execCommand( 'delete' );

This will give you the underlying whole surface.

3) Create a reference plane rectangle in another location.

4) Either select the trimmed surface of interest or select all of the surface trim curves, including the ones on the side.

5) Use the Flow command, selecting the untrimmed surface (duplicated in place) as your reference.

6) Select the plain surface to the side for the Flow target.

7) Your surface trim curves should now be transferred to the new plane.

Essentially the UV trim data should be "unwrapped."

You should be able to use the Flow process in reverse.

An no, I've had some strange results trying this at times, but it's worth a try.