Hi Wimverbe!

I don't know if anything I'm going to say below makes sense, but I hope it helps...

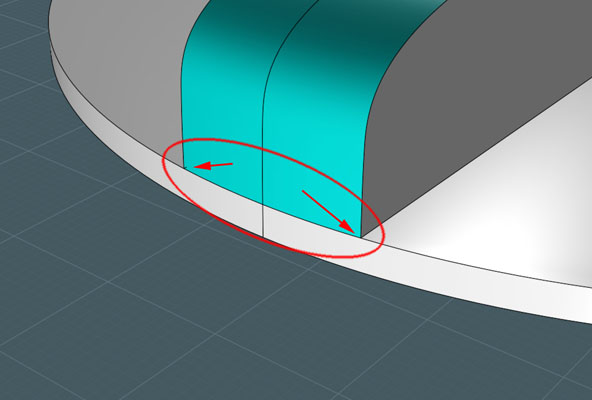

The problem is with that seam area where the top handle shape meets the round bottom shape.

The Fillet mechanism is running into a problem at the intersection of that seam.

Plus, you have two completely separate surfaces making up this object and they just happen to meet where Fillet needs to deal with all kinds of angles.

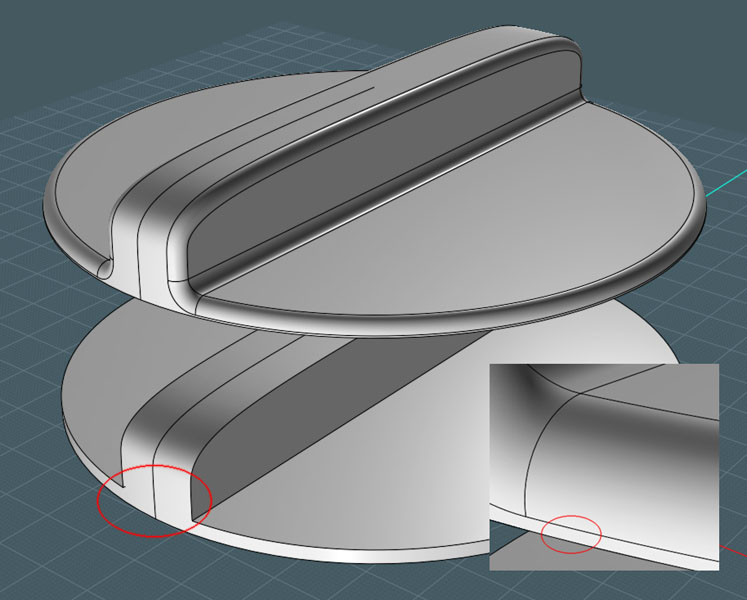

I reconstructed the entire shape an then Boolean Differenced out the negative space to create a solid shape that does not have that seam located at those corners.

You cannot simply Boolean Union two shapes together to make a seam disappear, the seams are a natural byproduct of the surface's edges that define them.

Also, Fillet will sometimes fail if the distance of the Fillet radius matches that of the entire distance to the other edge of the object. I'n my practice, I usually let the Fillet fall short so that it has some surface left to use as the adjoining side.

Someone else may have a better explanation, and I know there was a previous post dealing with this issue.

Maybe this might be a good case in the future for the NURBS library engineers to look at.

For filleting, it is better to have cleaner, "Whole-istic" surfaces. Fillets have issues around seams.

|