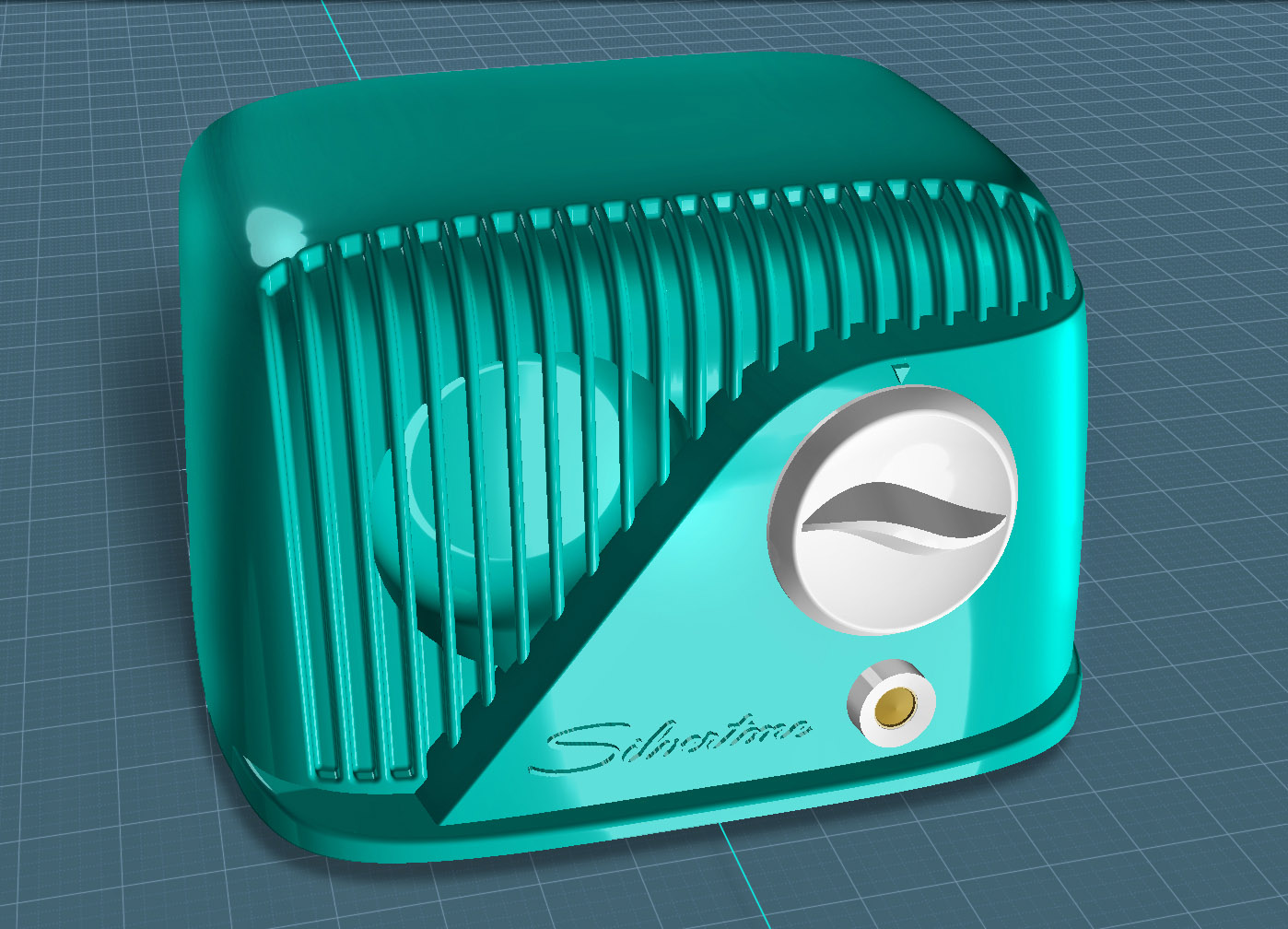

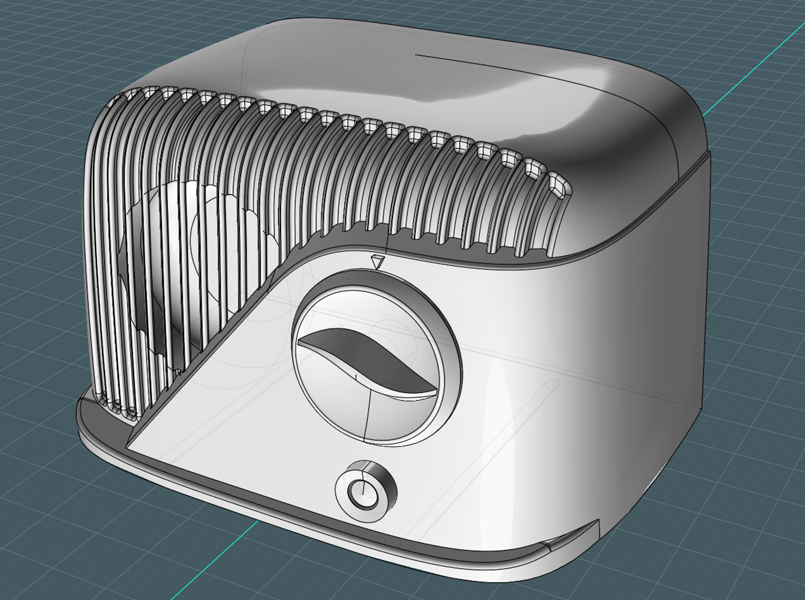

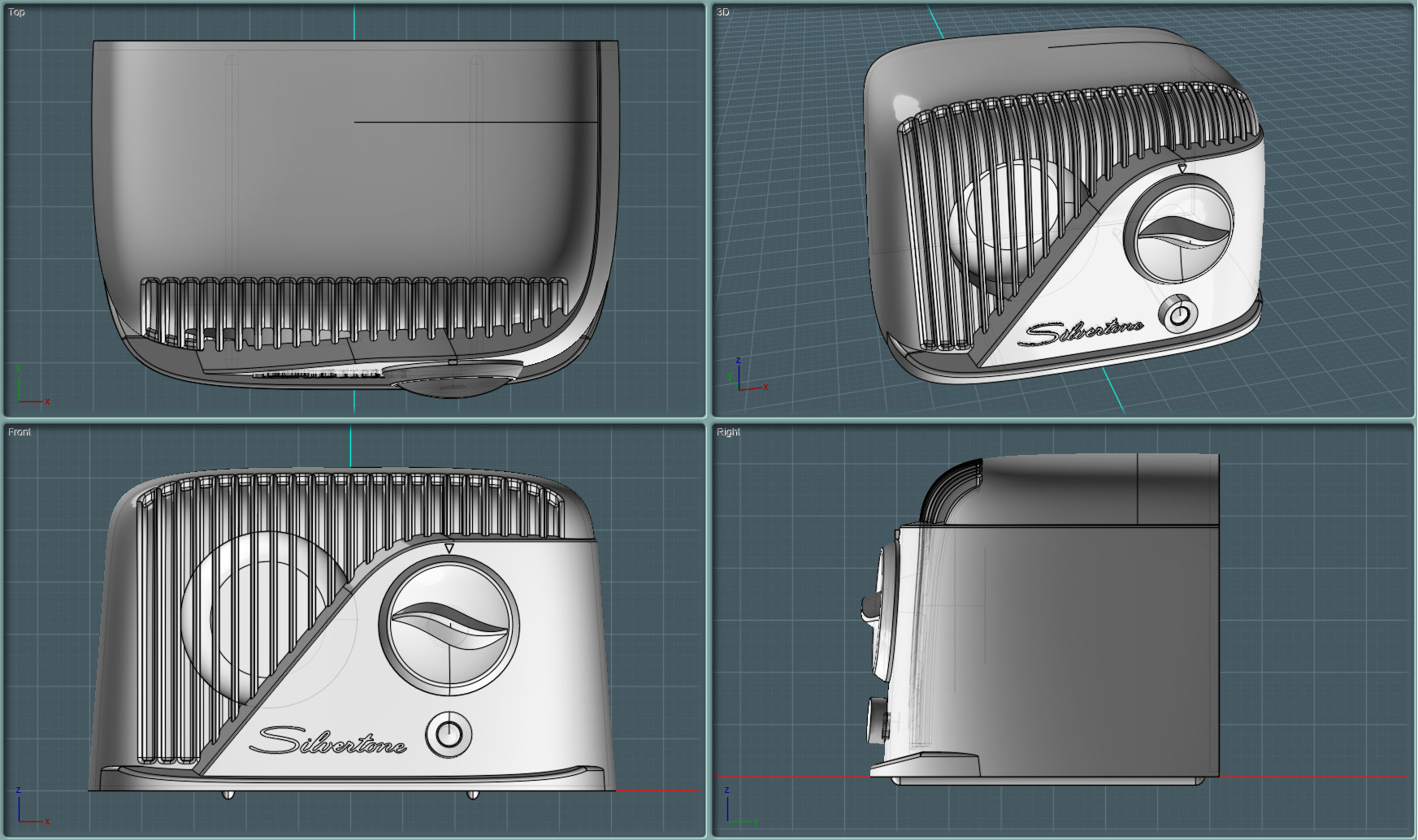

This is a MoI modeled approximation of a Silvertone five tube AM radio,

sold by Sears and Roebuck. Model 9000, Chassis No. 132.857.

It was manufactured in 1952, made with a polished Bakelite plastic.

The detailing, from a design standpoint is exquisite when examined closely.

These were all made in a brown color only,

as this was an "economical" radio.

One graces my collection and has begged to be modeled for some time.

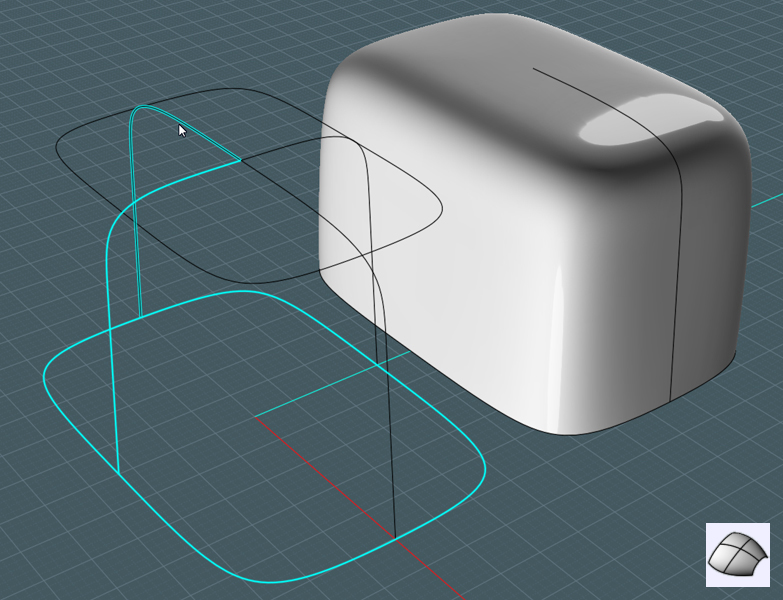

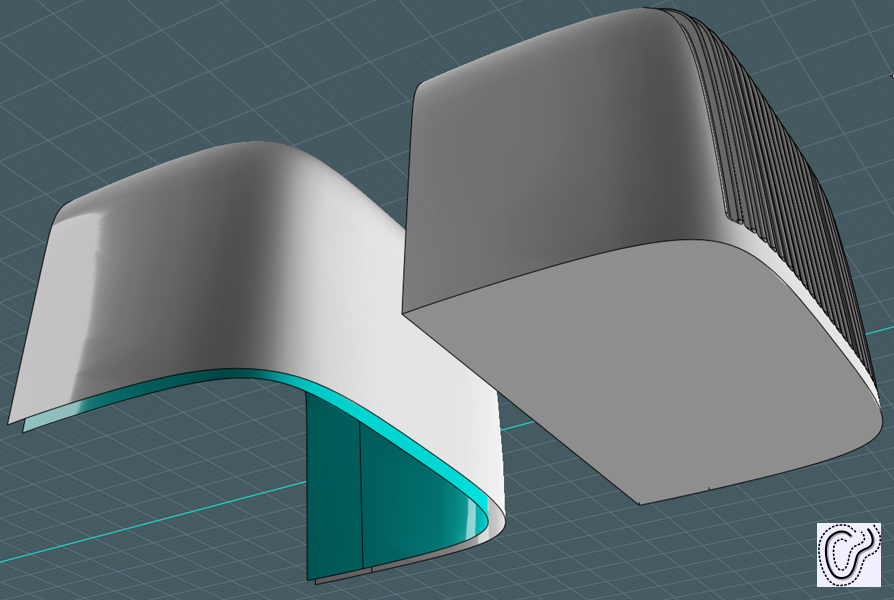

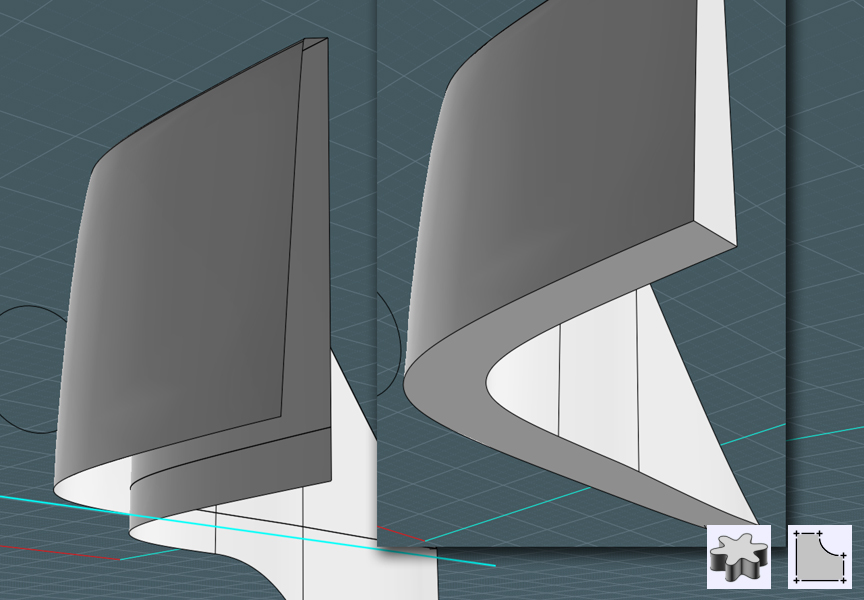

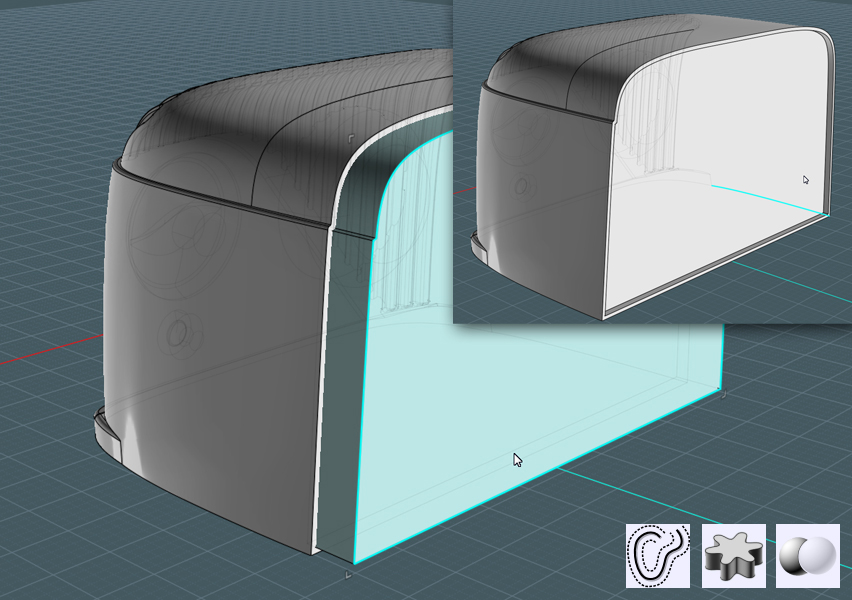

Create the body of the radio by making a Network:

1) Create the base profile

2) Copy the base profile, bring it up and make it a little smaller

3) Creat a side profile that ends at the center

4) Copy, rotate and position the profile so that they represent all sides and end, touching at the center

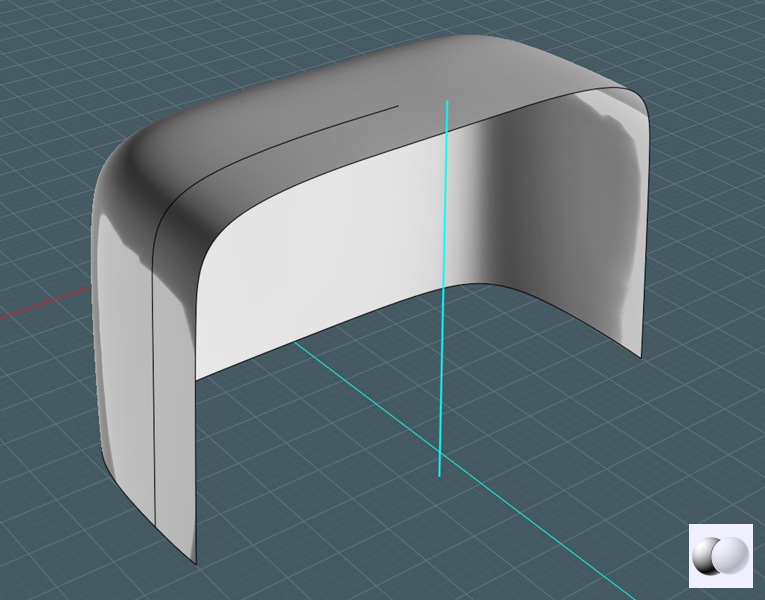

Trim the shape:

1) Draw straight line in the side view to represent where the back of the radio will be - position not crucial

2) Boolean Difference the body shape and delete the back

Adjust the shape:

1) Use Scale 1D to adjust the depth of the shape

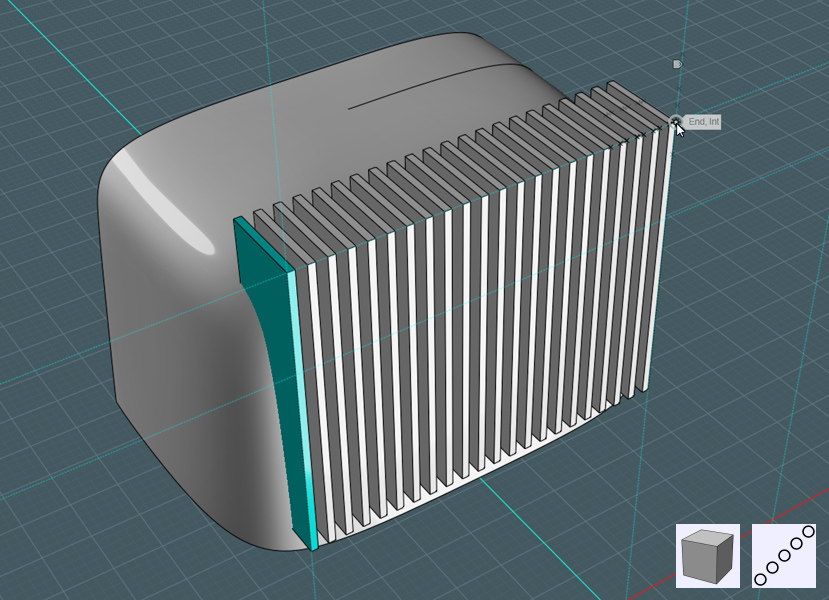

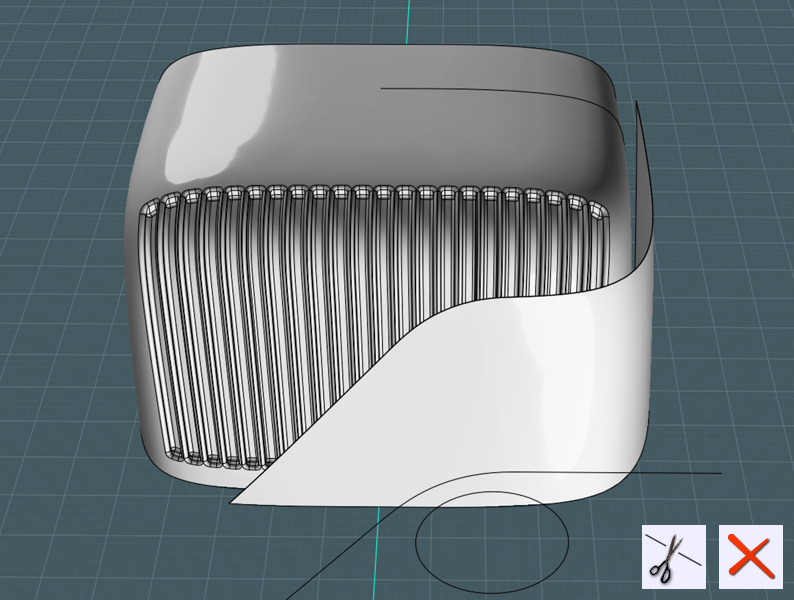

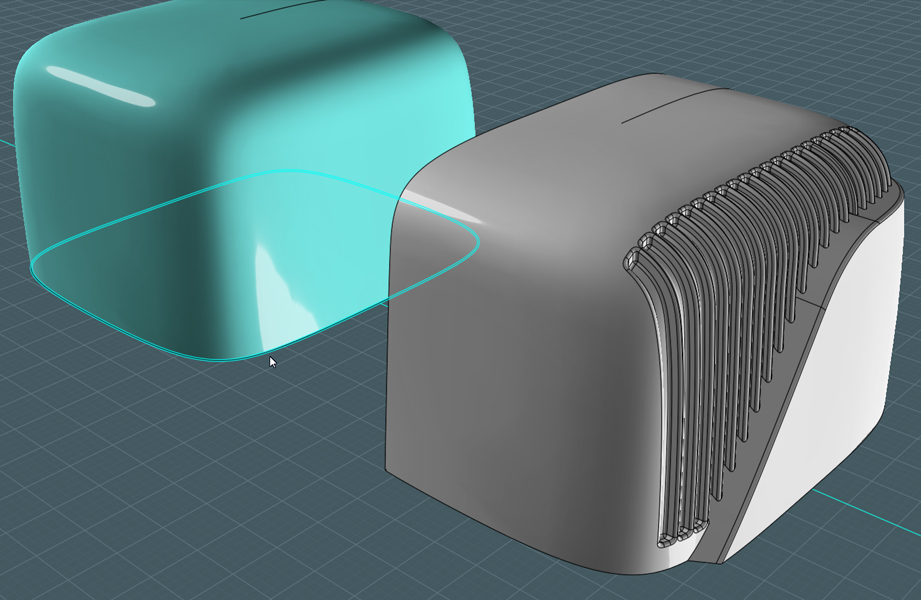

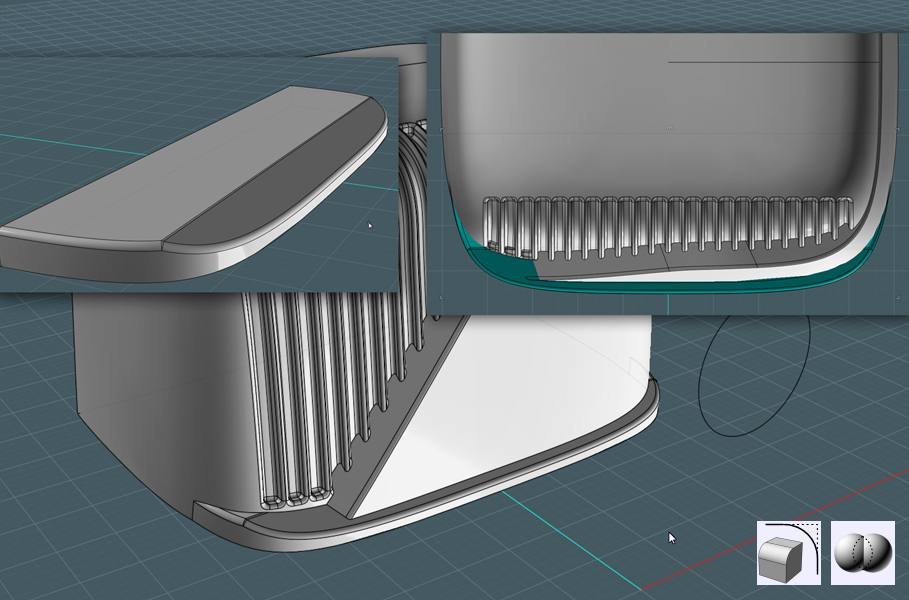

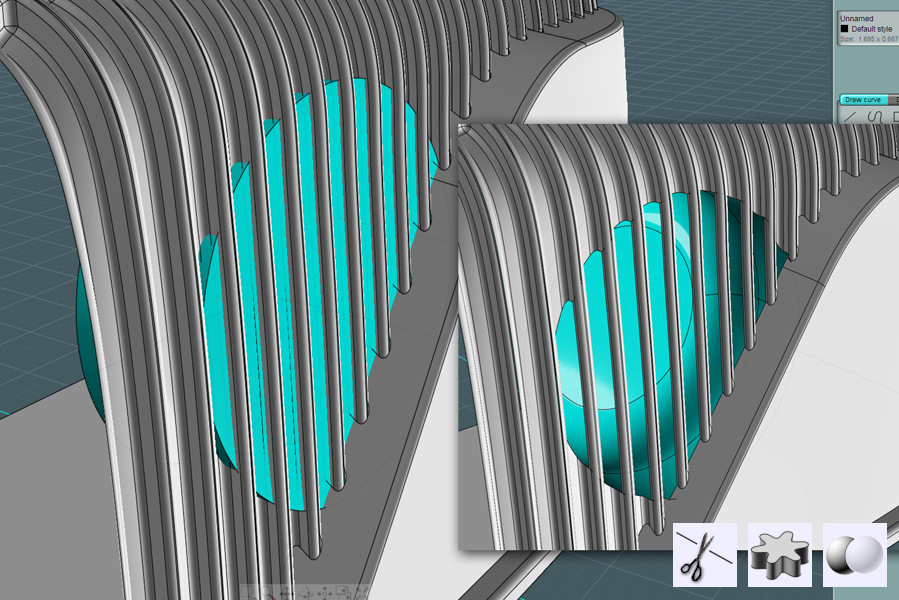

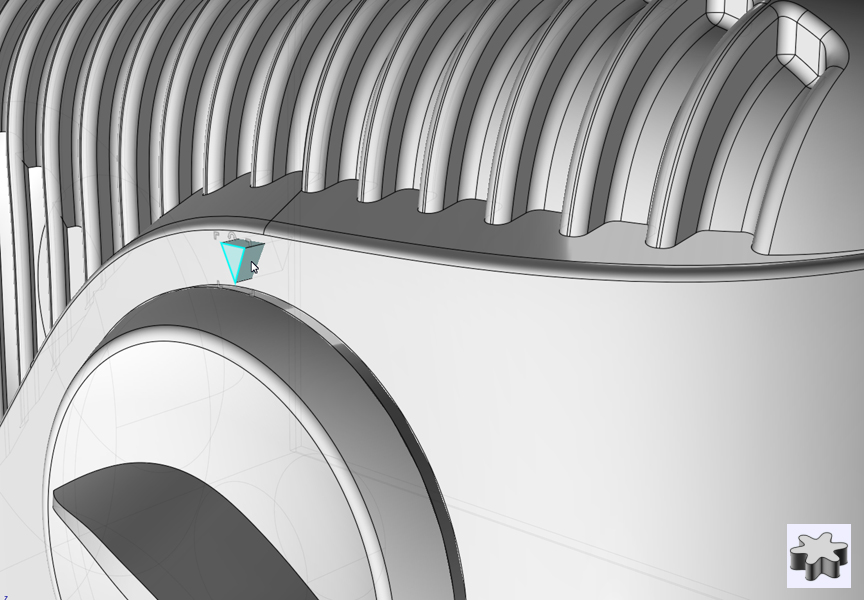

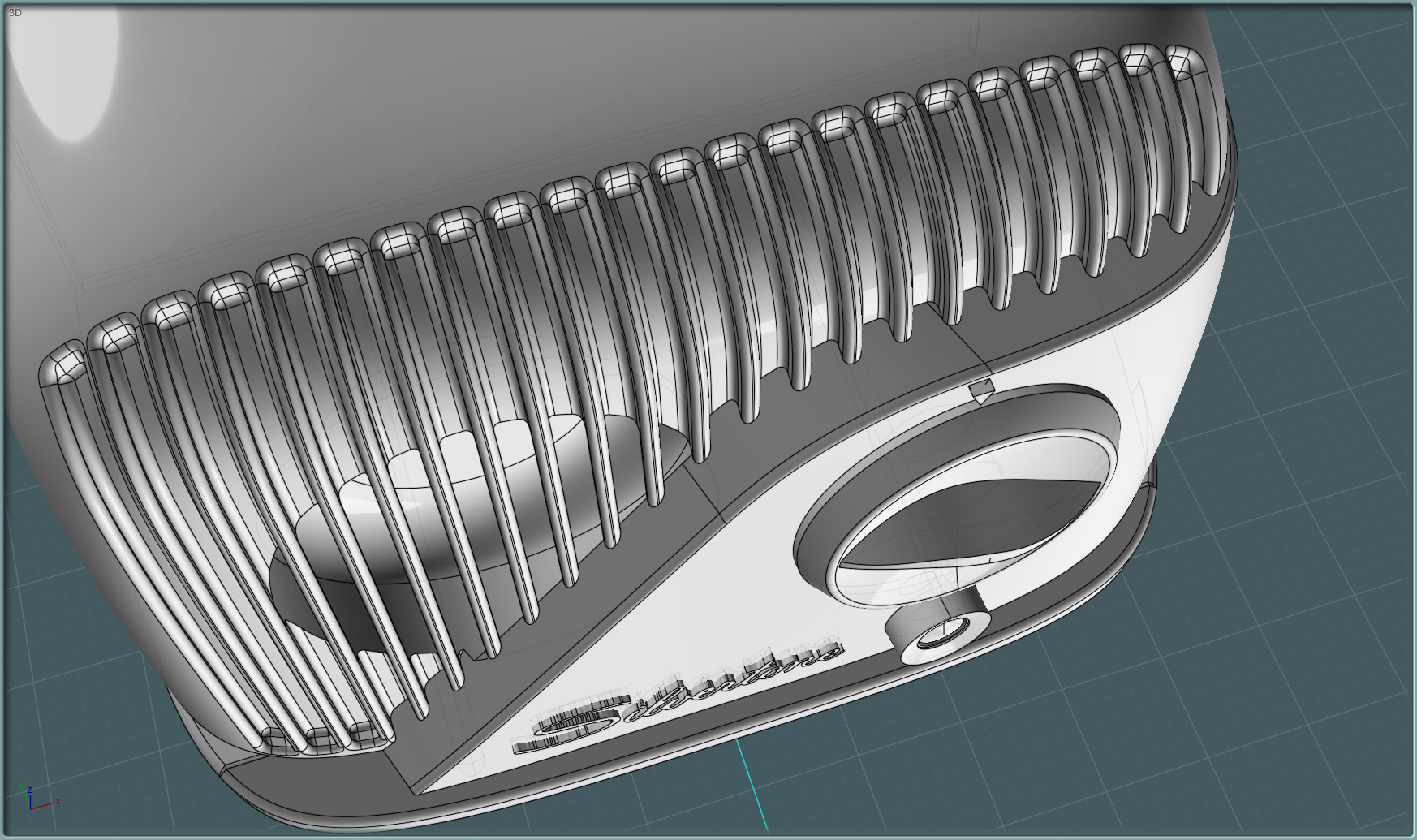

Create Grill Cutouts:

1) Create a representative box that is skinny

2) Array with copies, until you create enough to fill the front

3) Adjust alignment with the body, according to the method of your choice

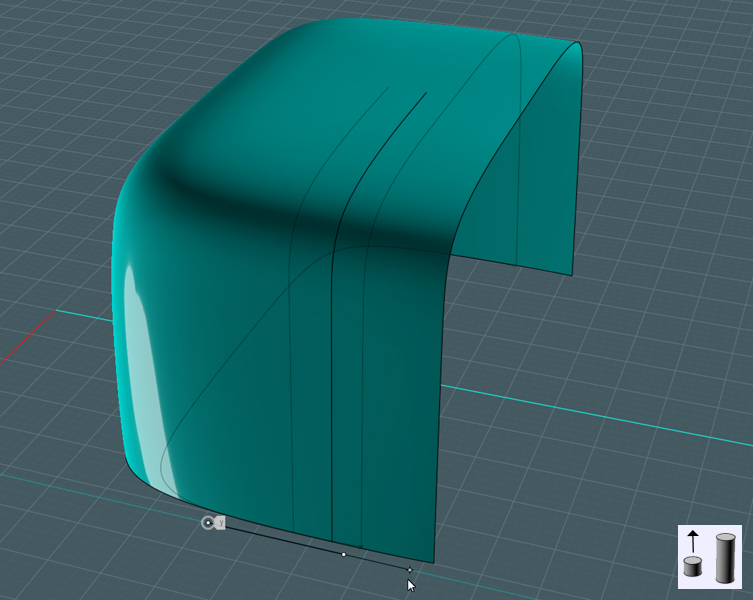

Make original body shape a solid:

1) Bridge any pointy edges with a line

2) Select edge curves and Planar them

3) Join all surfaces to make a solid

- Keep a copy of this solid body shape

Make an inner copy of the body to represent where the grill holes sink to:

1) Select just the ouside surface of the body shape

2) Offset the surface to the inside

3) Run through prior steps again to make the new surface a solid, but not crucial

Trim grill shapes with the sunken inner shape:

1) Run Boolean Difference or Merge to trim off the inside excess of the boxes

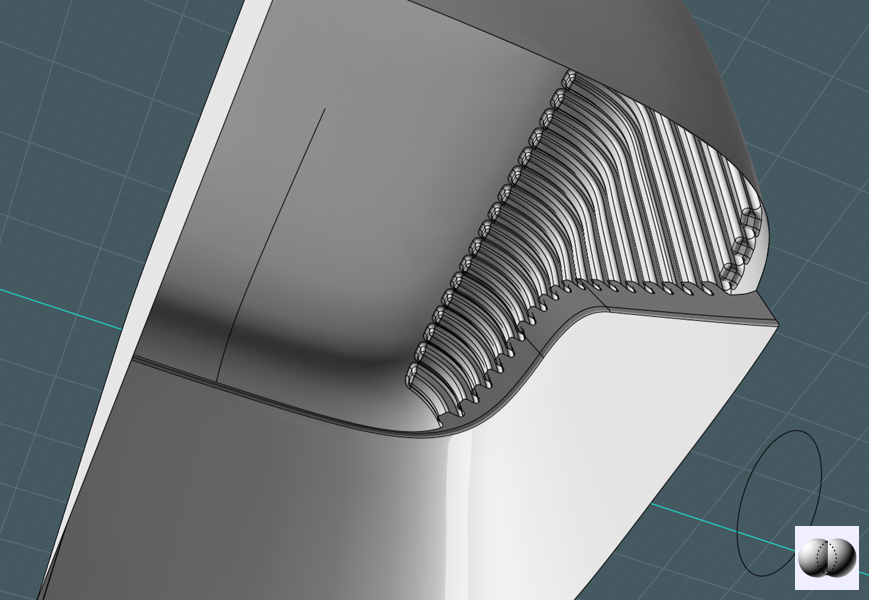

Creat grill indentions:

1) Boolean Difference the body shape with the grill blocks

2) Fillet the edges if possible - selecting every curve that makes up the grill hole will be easier on the Fillet command

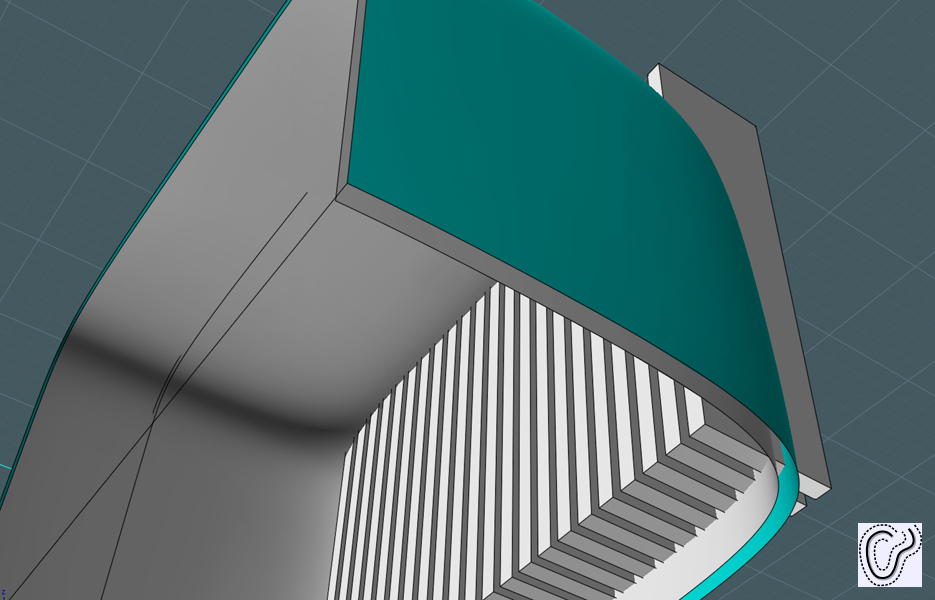

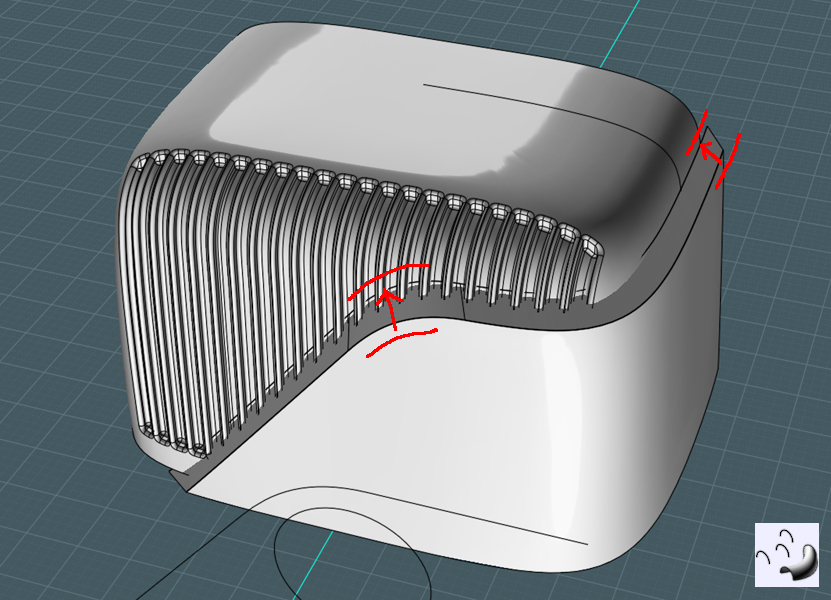

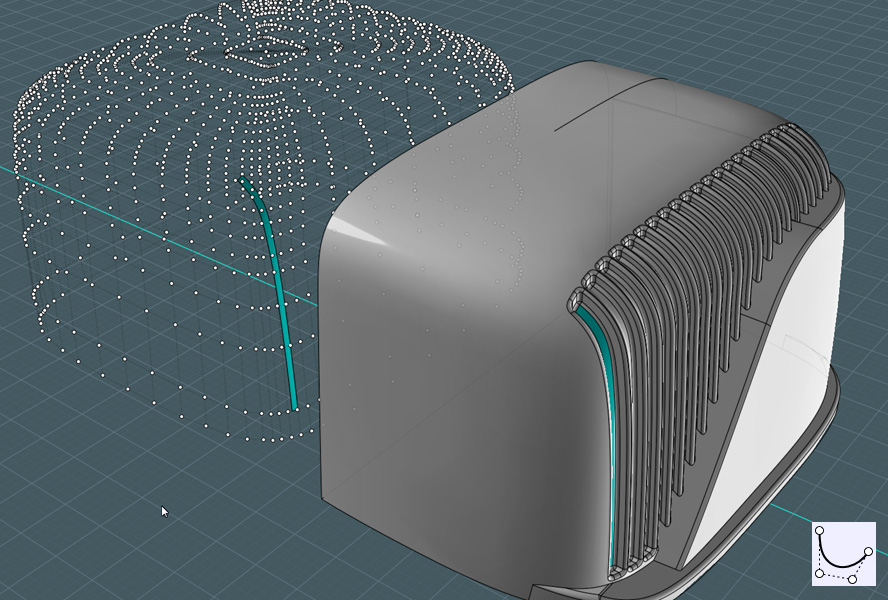

Make outer shell of body shape:

1) Select the body shape - either untrim or obtain your saved copy

2) Offset the surface outwardly

Make shape of body contour feature:

1) Draw curves to represent body feature

2) Project the curves to the new larger body shape

Trim new shape:

1) Trim the curves on the surface to the surface

2) Delete unwanted surfaces

Create shelf for body feature:

1) Copy edge curves of surface and move/scale them inside the radio solid

2) Perform a Loft command to create the shelf

Move shelf to create a gap:

1) Select lofted surface and move it so that there is a little gap in between

- This was done because Fillet failed

Loft edge to make a custom fillet:

1) Select edges from both sides

2) Loft to make new rounded surface

3) Join together

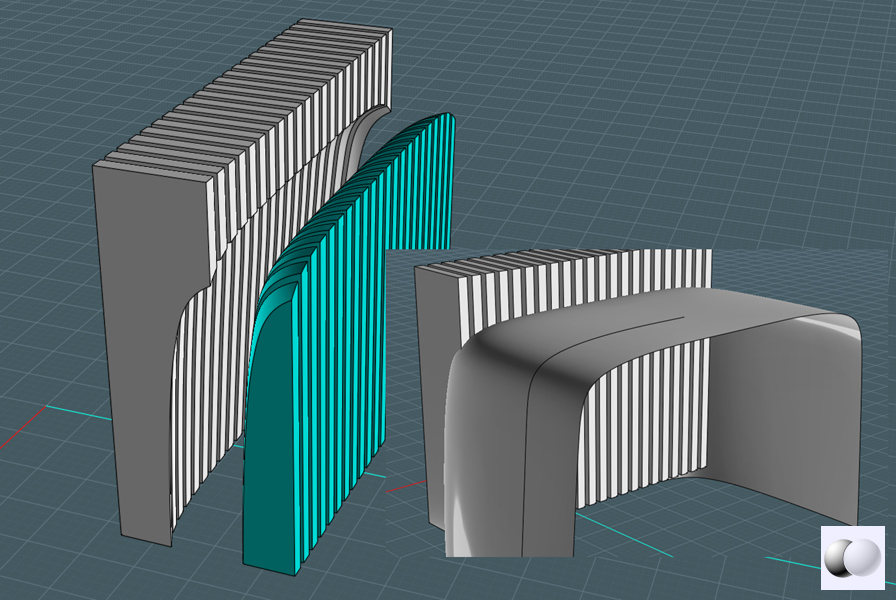

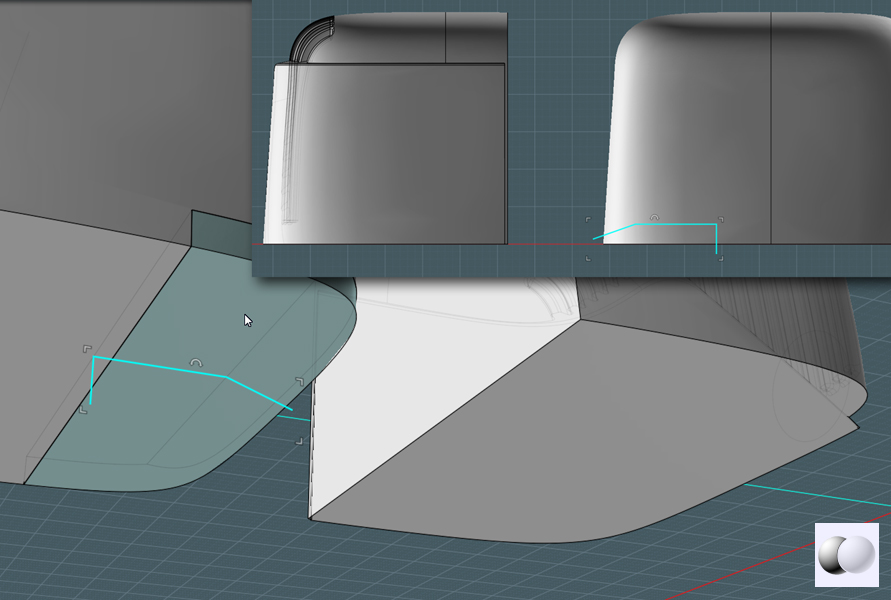

Make the body feature a solid:

1) Extrude back edge

2) Boolean Difference the bottom and back edges to make flat

3) Add curves as needed and Planar

4) Join

Weld body feature to body:

1) Boolean Union the two solids to produce a new solid

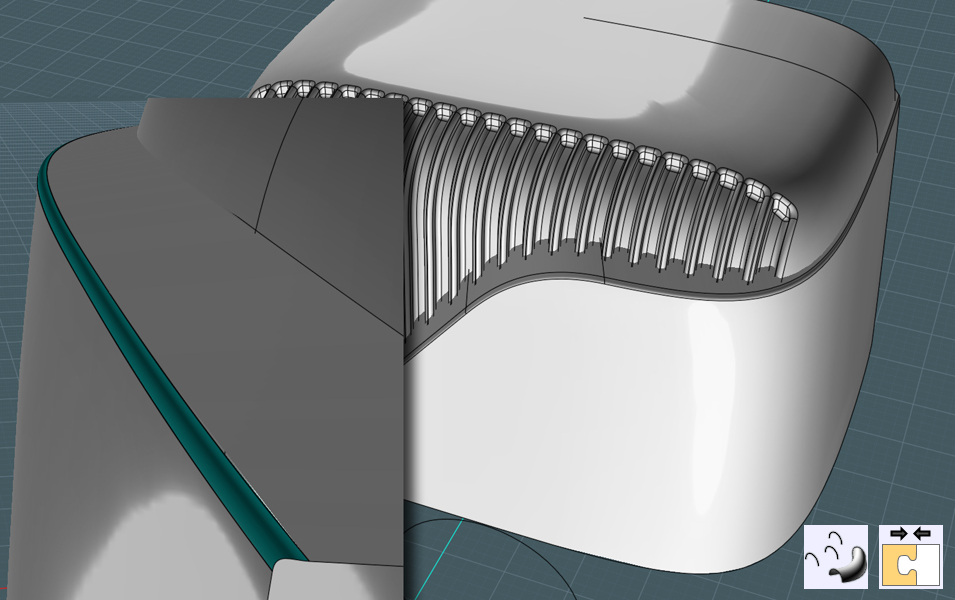

Bring back original body shape:

Creating foot feature:

1) Create profile curves

2) Boolean Difference to get a new shape

Position and incorporate foot feature:

1) Fillet edges of foot shape

2) Position to front edge

3) Boolean Union

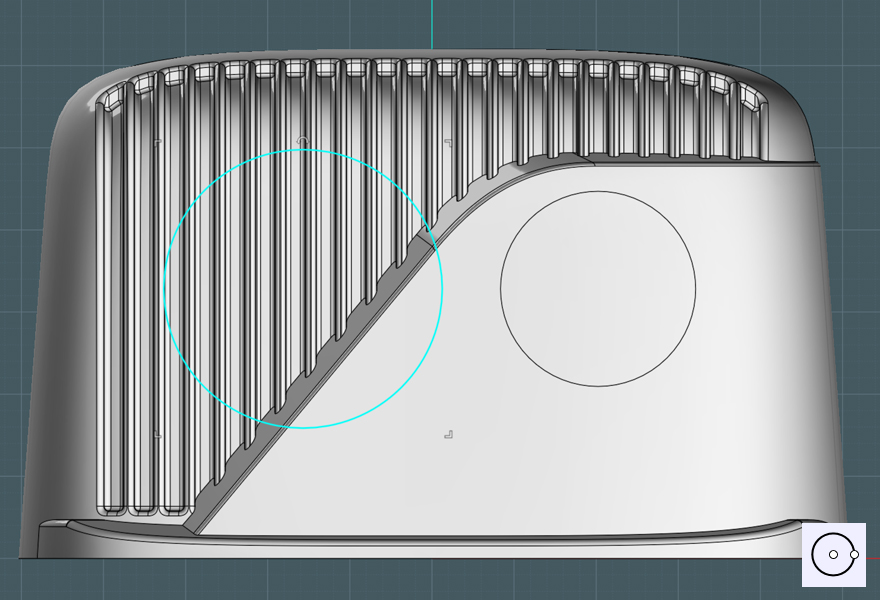

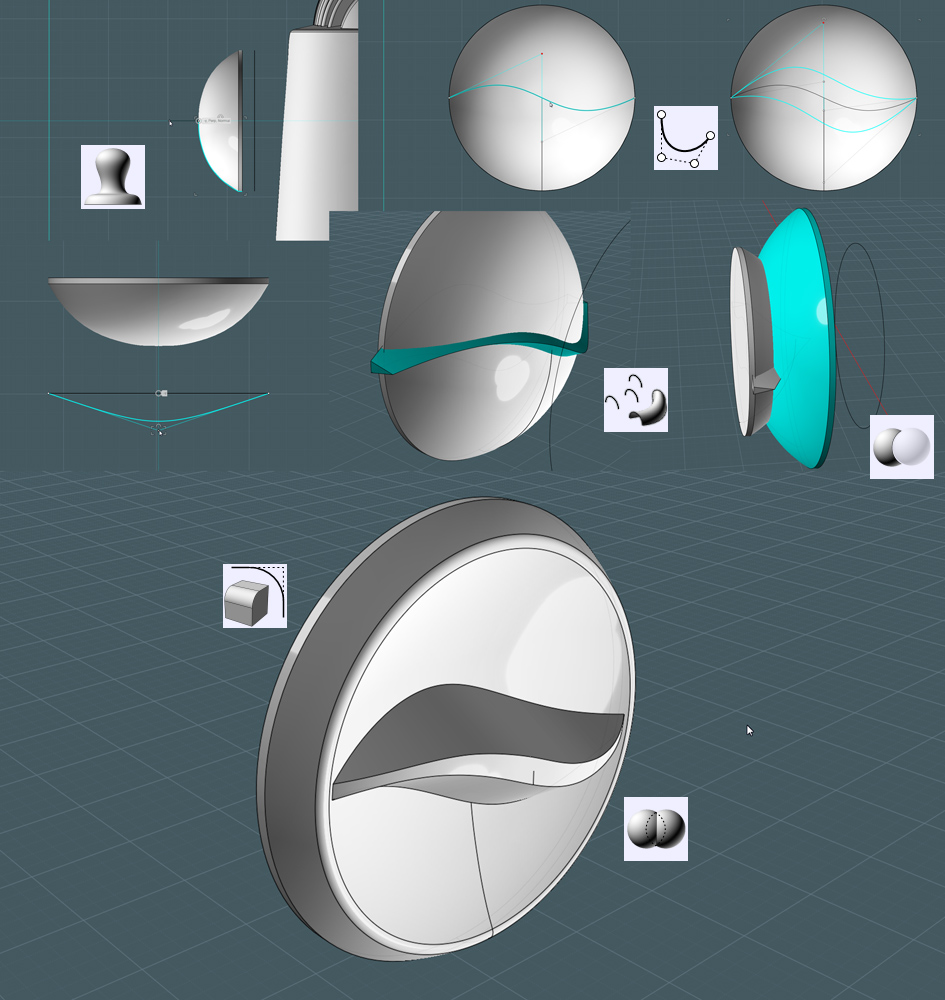

Circle for speaker:

1) In Front View make a circle

Get inner shell shape of body solid:

- I copied a surface from the inside hole of the frill indent and deleted the edges to get back my inside shape

What we need is a sunken shape to trim a speaker hole out of the body without coming too close to the surface

so we are left with grill bars

Project Circle for speaker hole:

1) Project circle into inner body shape

Cut shape from inside of grill area:

1) Take cutout circle surface and extrude the edges to make a cylinder

- Boolean intersecting a cyliner with the body shape would have been easier ;-)

2) Ensure that the new cyliner is a solid

3) Boolean Difference the cylinder from the body

Create tuning dial:

- Use Revolve, Freeform Curves, Loft, Difference and etc

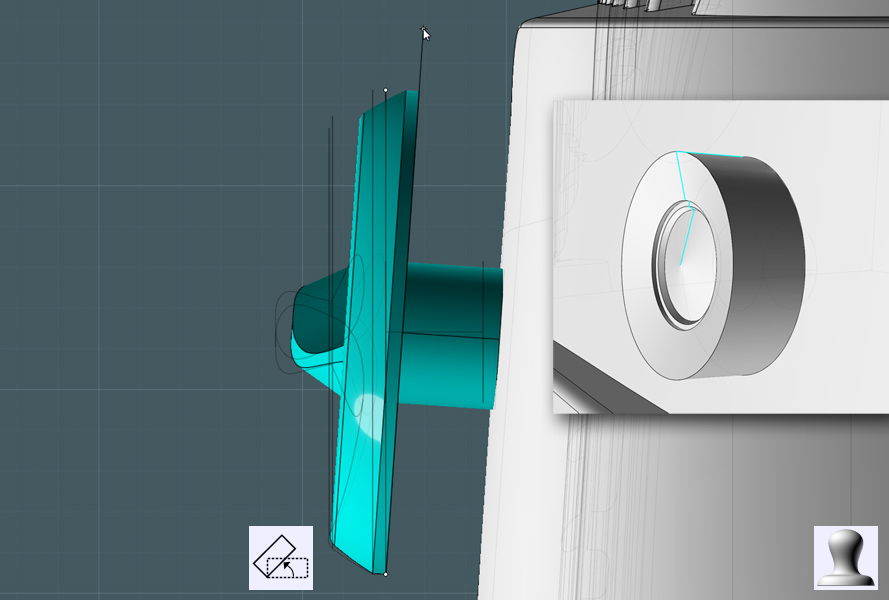

Position dials:

1) Use Rotate in all views to align the dial to the surface of the radio

2) Create smaller volume knob using Revolve

Create the back plate:

1) Select and copy the back exterior edge curves

2) Offset inside to make a more narrow copy of the edge

3) Use that profile to Extrude and inner shape - position to desired depth

4) Boolean Difference the shape to make the back plate and inset

Make dial pointer arrow:

1) Draw triangle using lines

2) Extrude shape

3) Position just outside radio body over the tuning dial

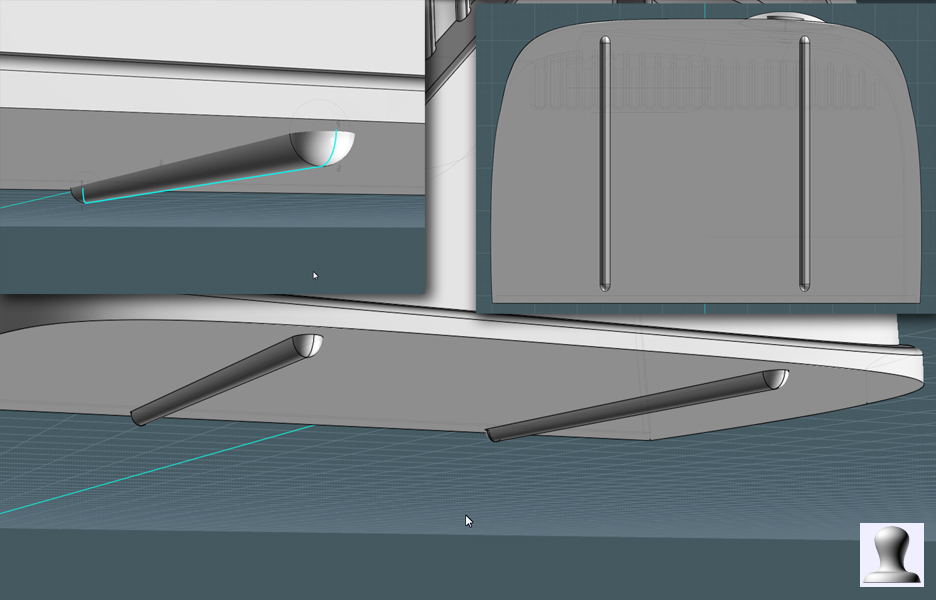

Make the feet:

1) Create profile shape

2) Revolve to make little strips

3) Position along bottom of radio

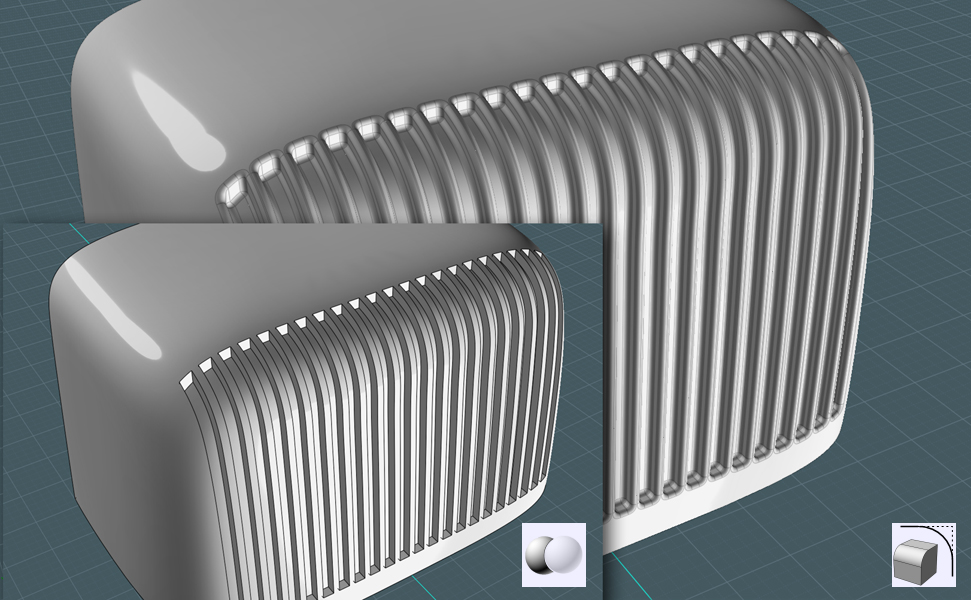

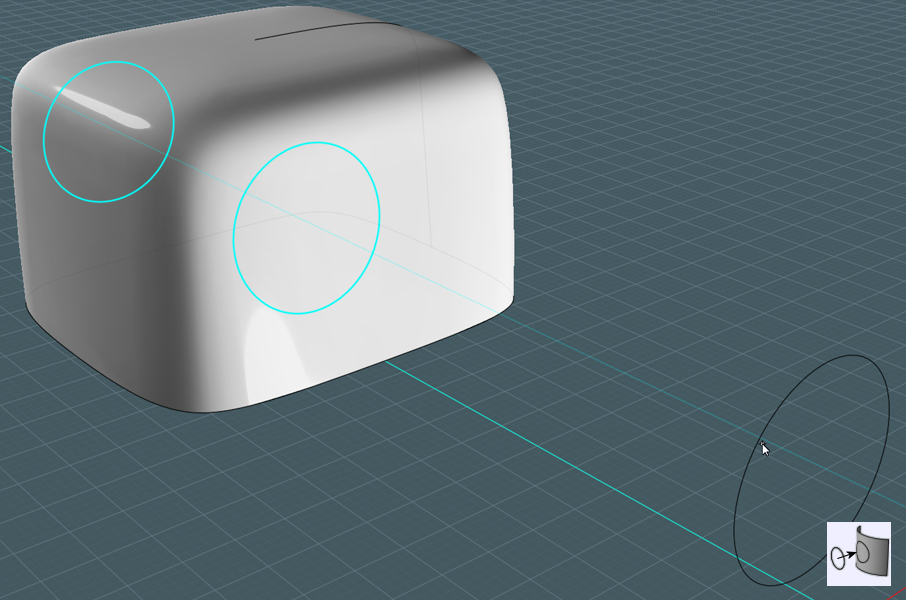

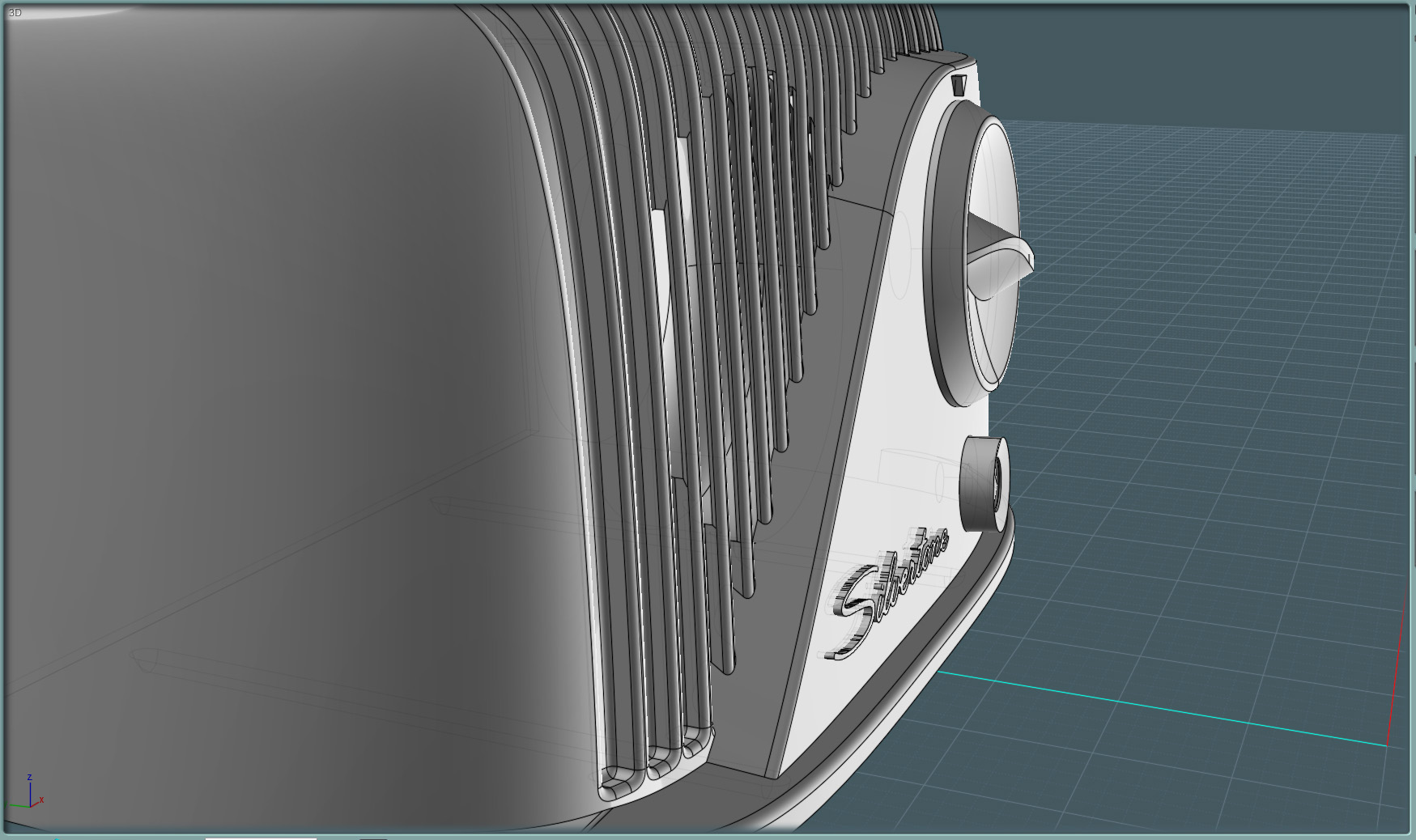

A final look:

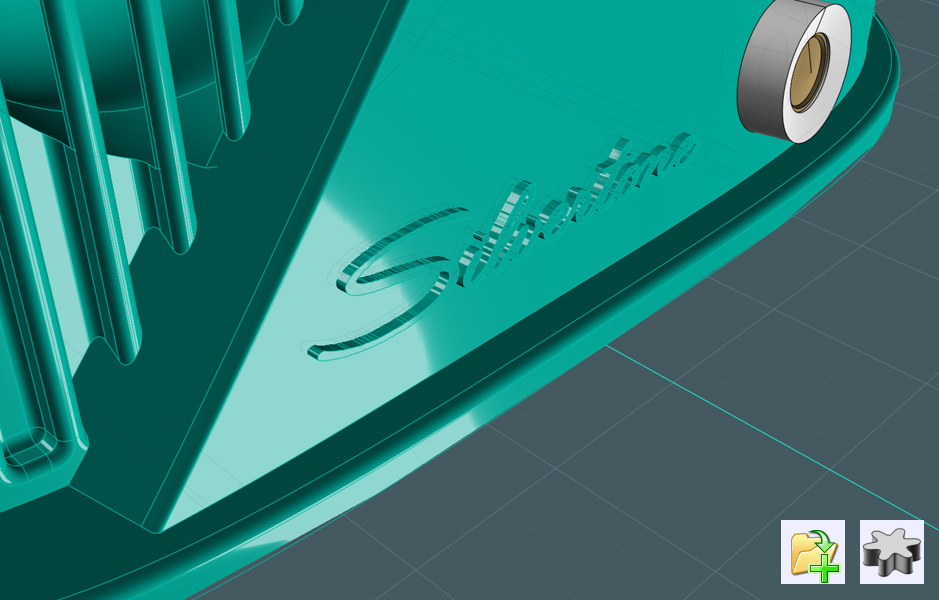

Place logo on surface:

1) Import curves for logo and Planar

2) Extrude

3) Place on surface

- Note: this would be a great time to try out the new Flow command.

The Flow command would allow you to create the indented numbers on the tuning dial as well.

From different angles:

Here it is!