You thought two blades were enough... Then science marched on and three blades made shaving move closer and more comfortable...

Then five... Still not enough?

Introducing the world's most advanced shaving system:

"The MACH-16"

Time Magazine raved: "...oh my AAAARGH... I can see bone!"

========================================

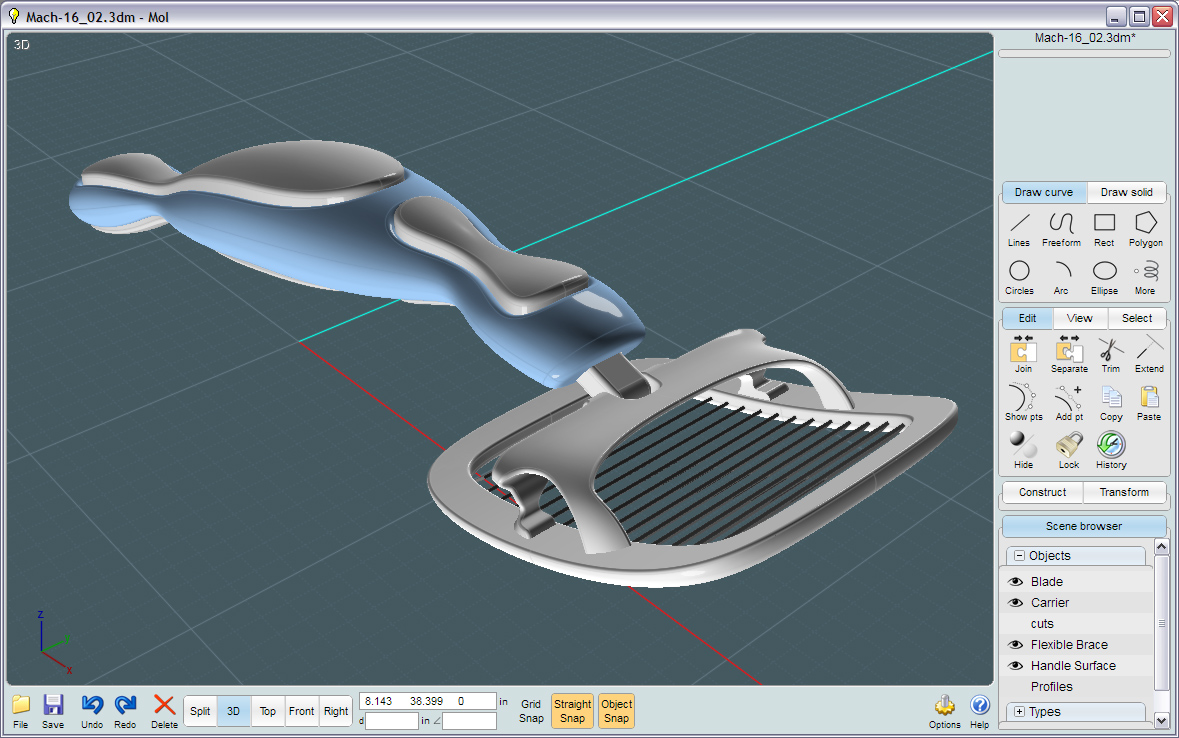

After a year, my tutorial for the "Mach-16 Razor" finally gets an actual tutorial!

I'm sure many have clicked on its link and was a little disappointed to see only finished model pics. ;-)

The reason for the delay was because I wanted to tailor this tutorial for the new-comers to MoI, and those who could use a few pointers.

I've experimented here with a format that is self-explanatory and easy to follow along. With a view of the UI so that you could see what button was pressed.

Later, I'll add a nice render along with a French translation.

Here is the original post:

(I do not have the original file as I was enjoying the trial version of MoIv2.)

========================================

http://moi3d.com/forum/index.php?webtag=MOI&msg=4388.3

The MACH-16 wet razor. Not only the closest shave, it goes ahead and takes care of next week's whiskers....

Took about half an hour.

(originally)

========================================

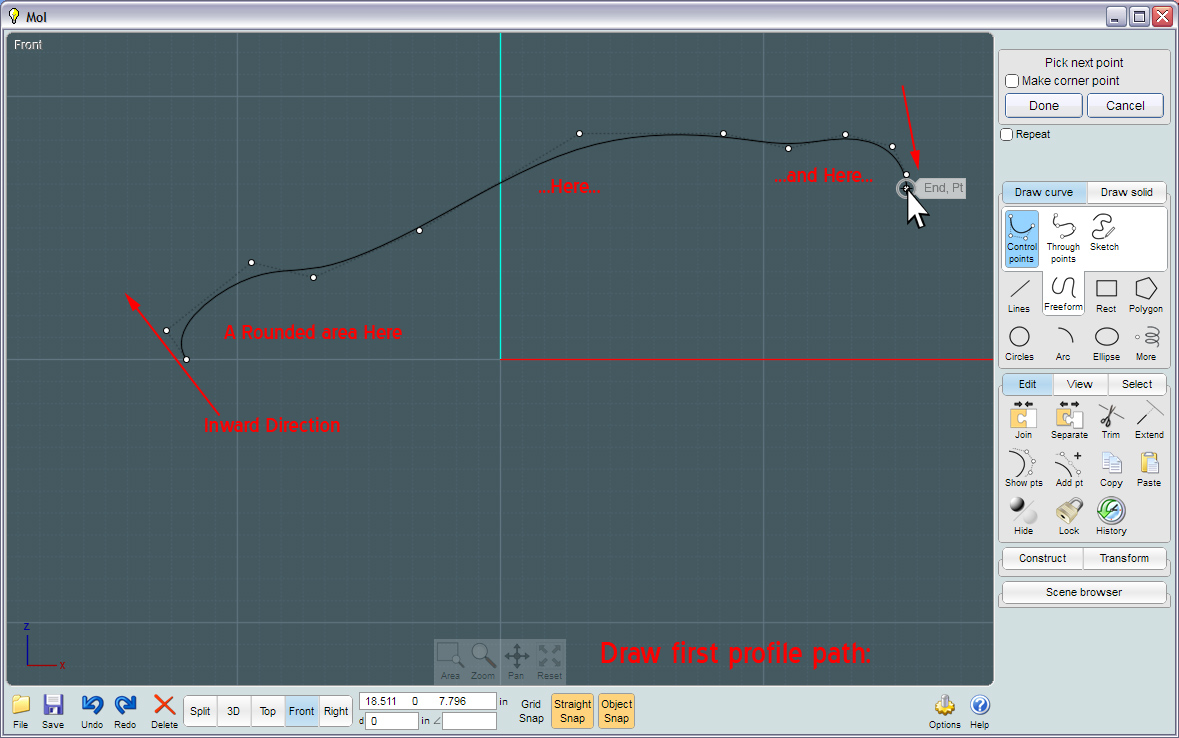

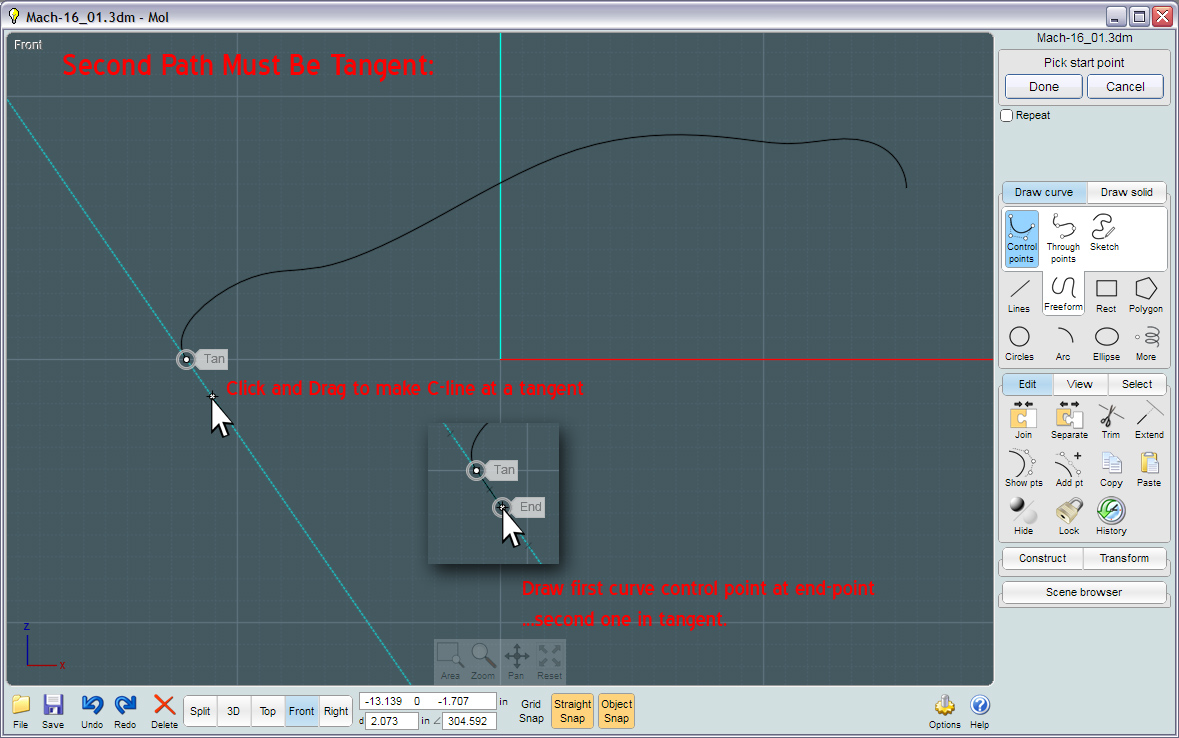

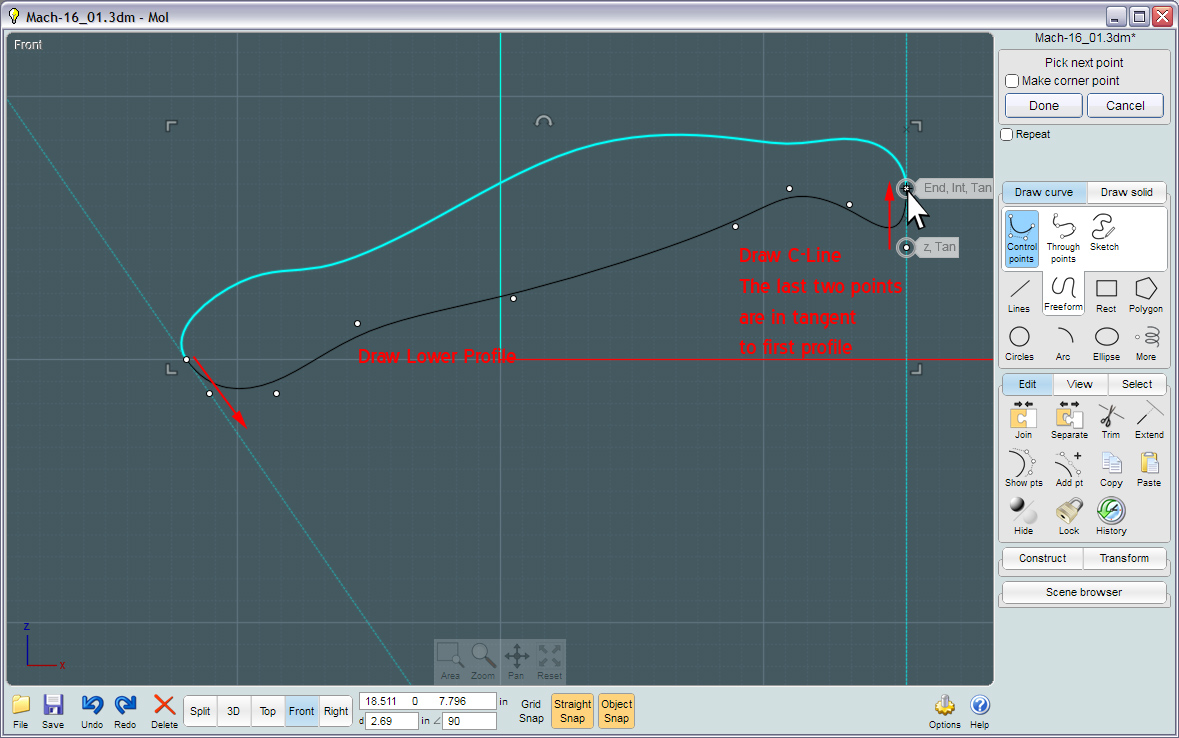

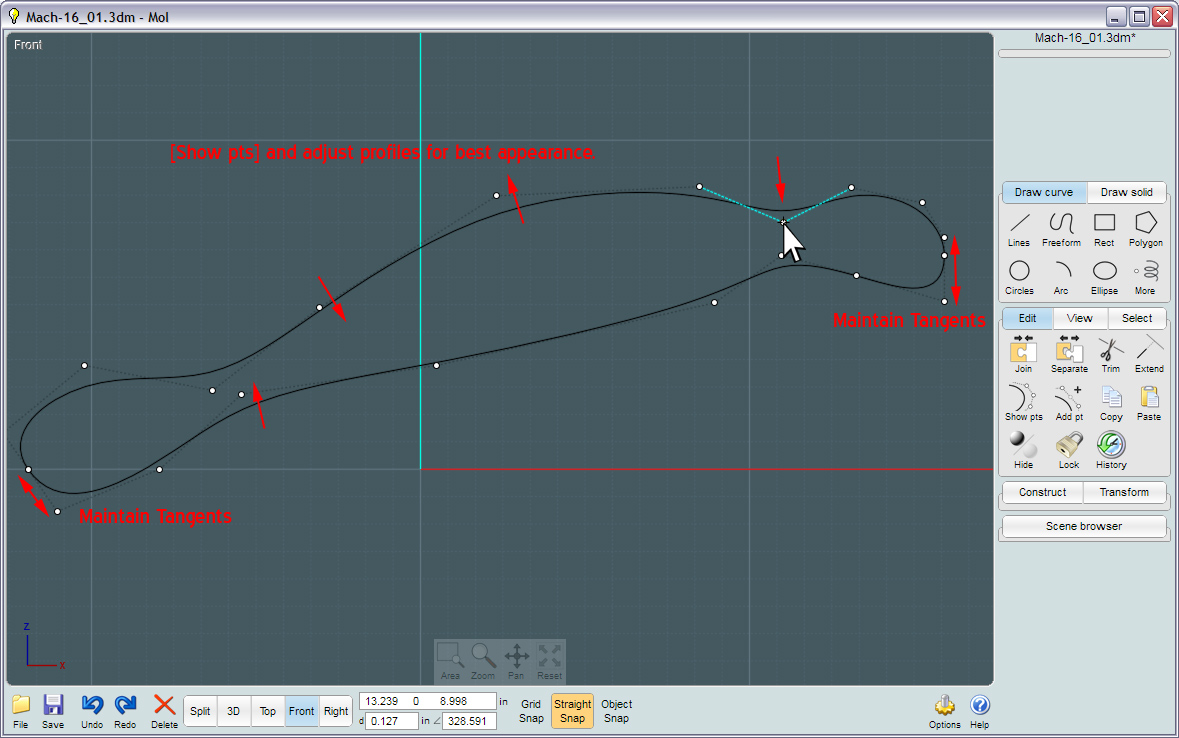

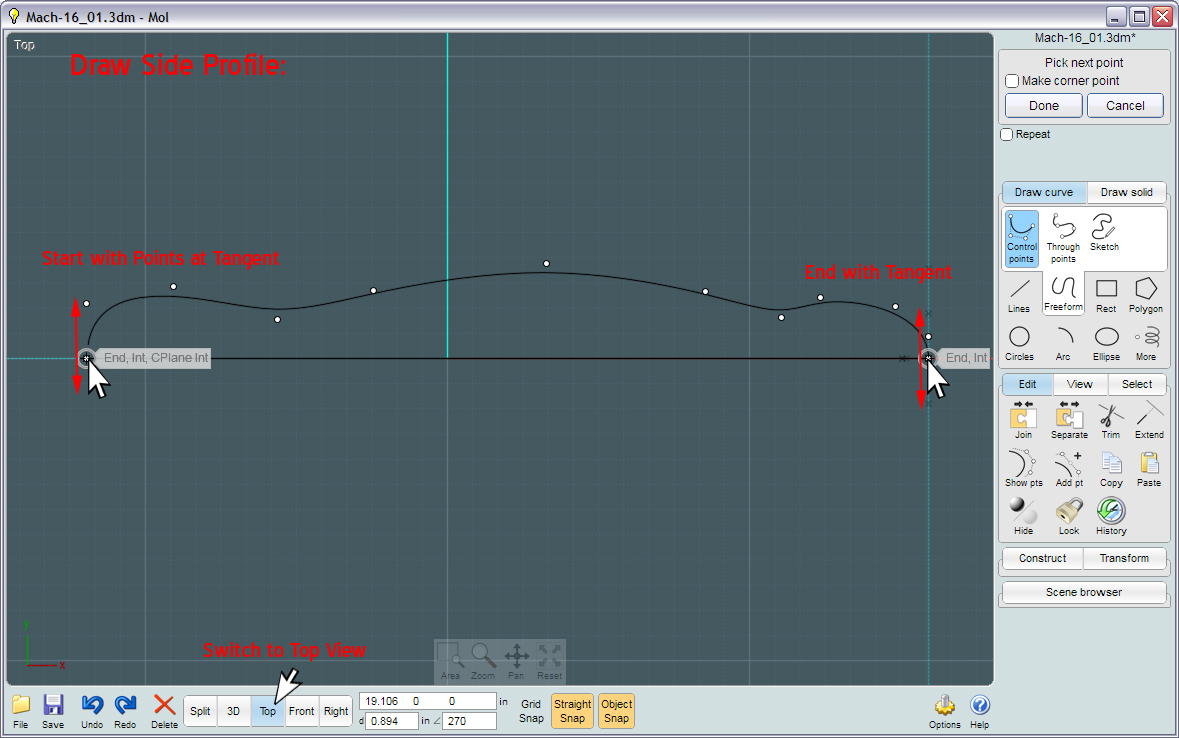

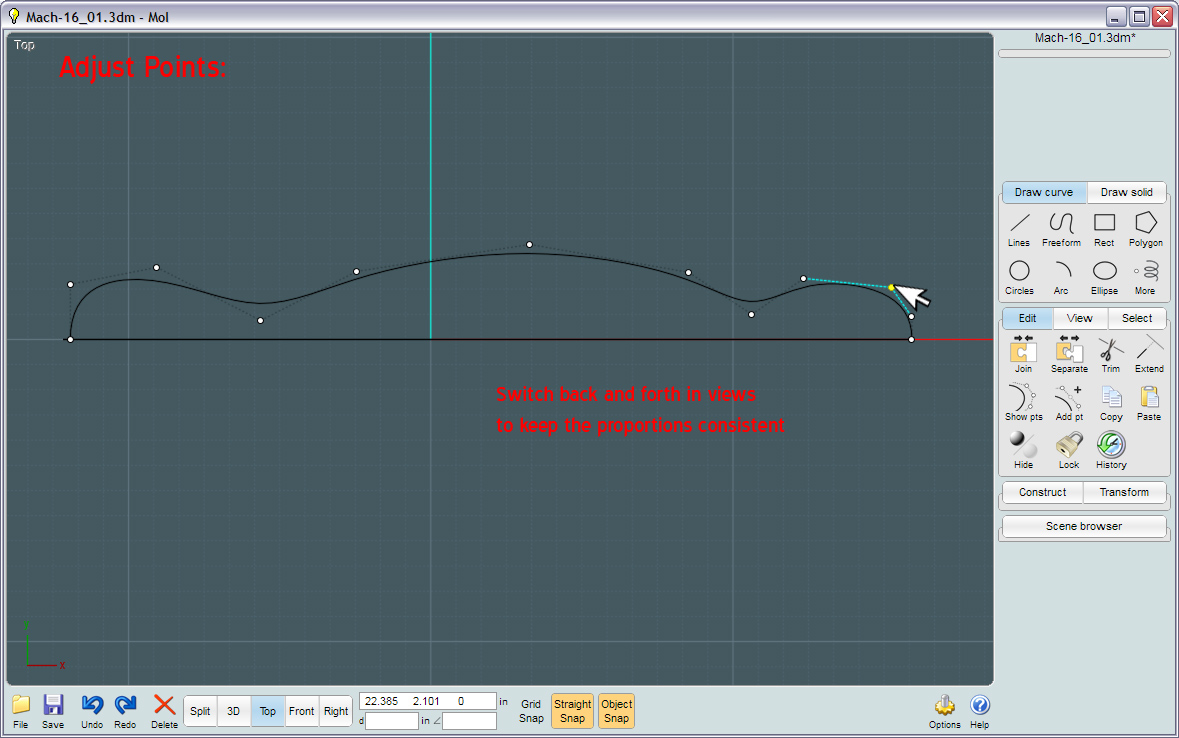

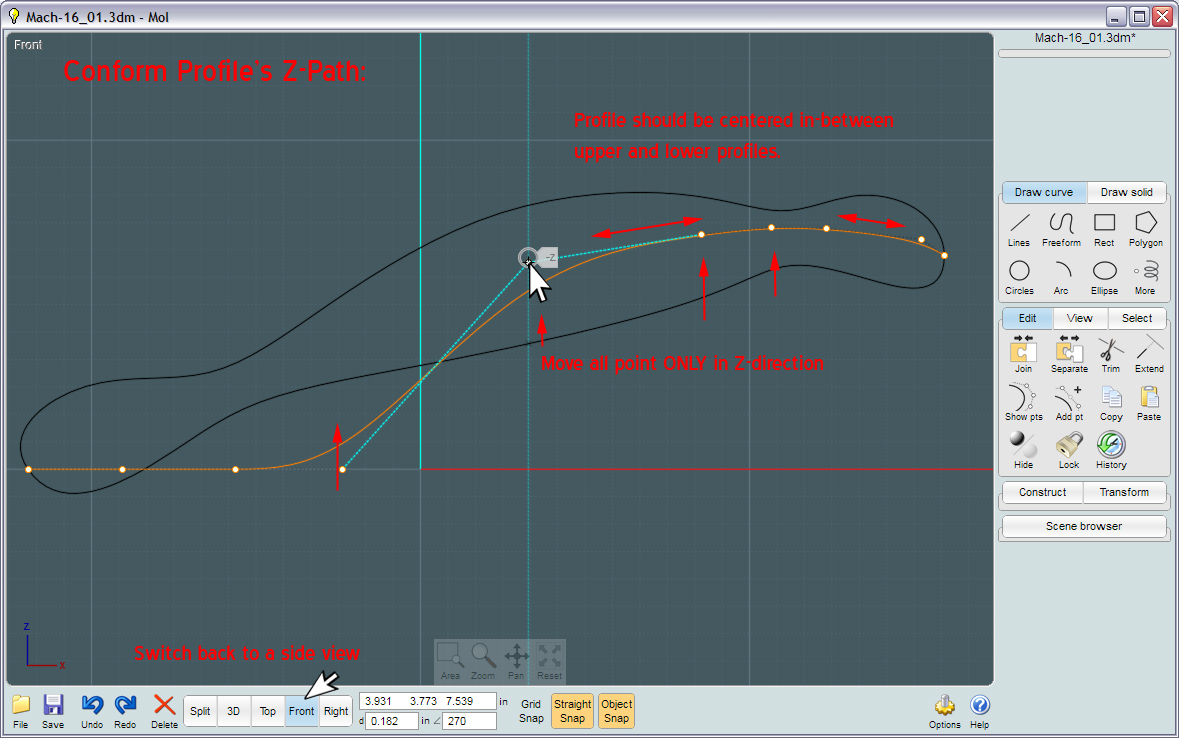

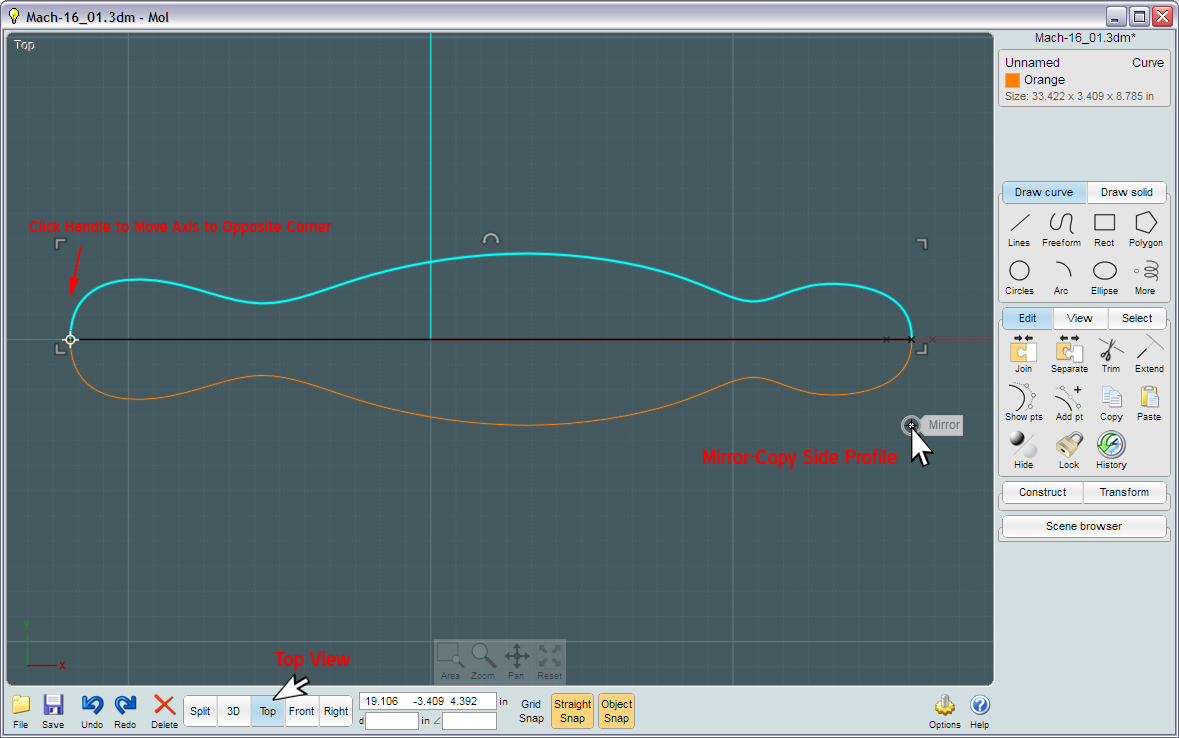

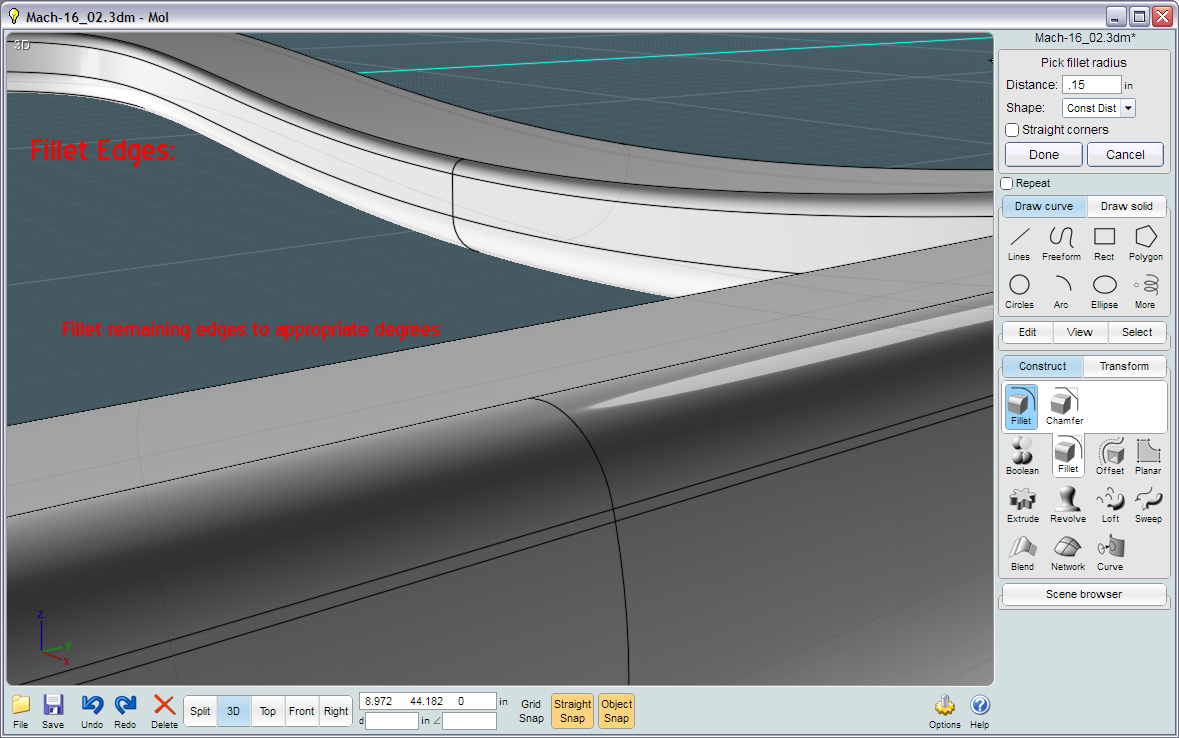

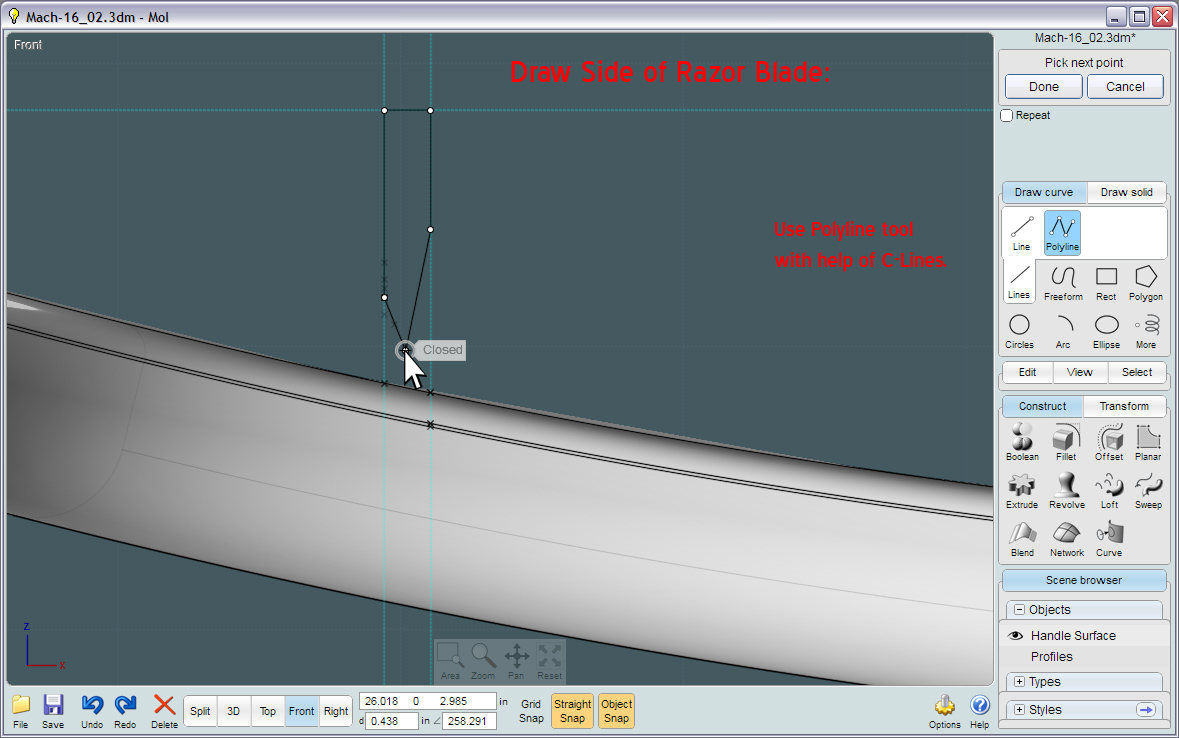

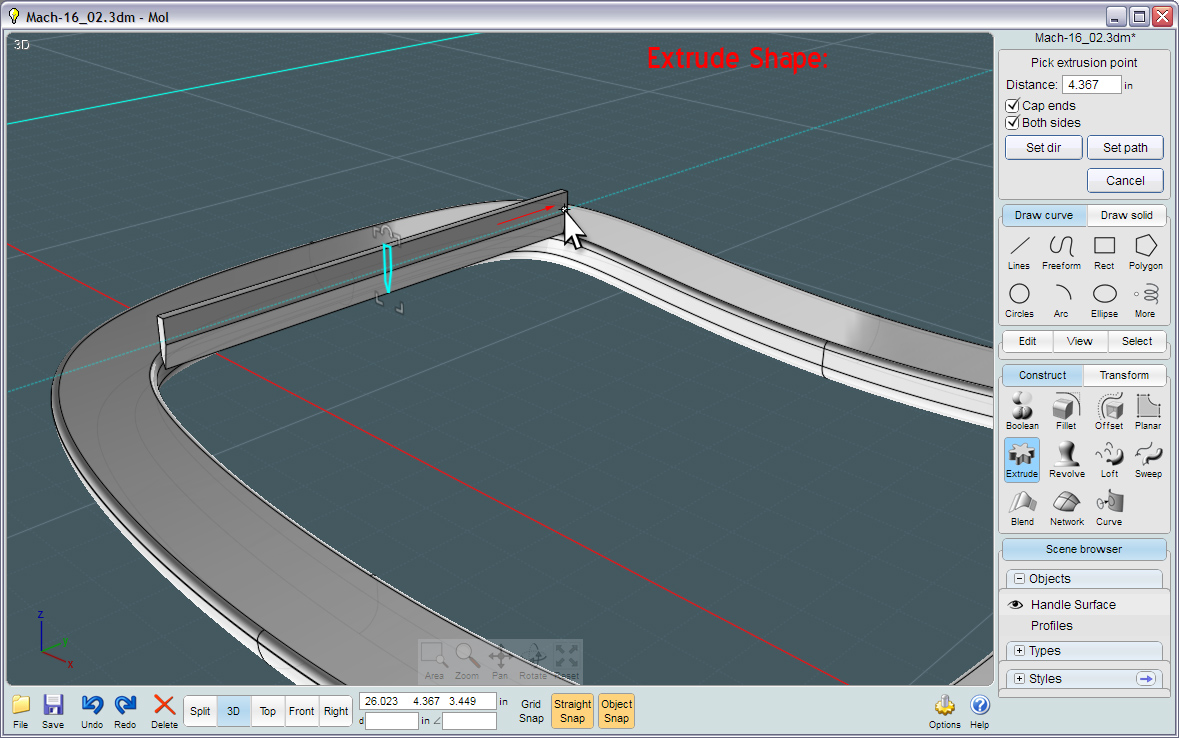

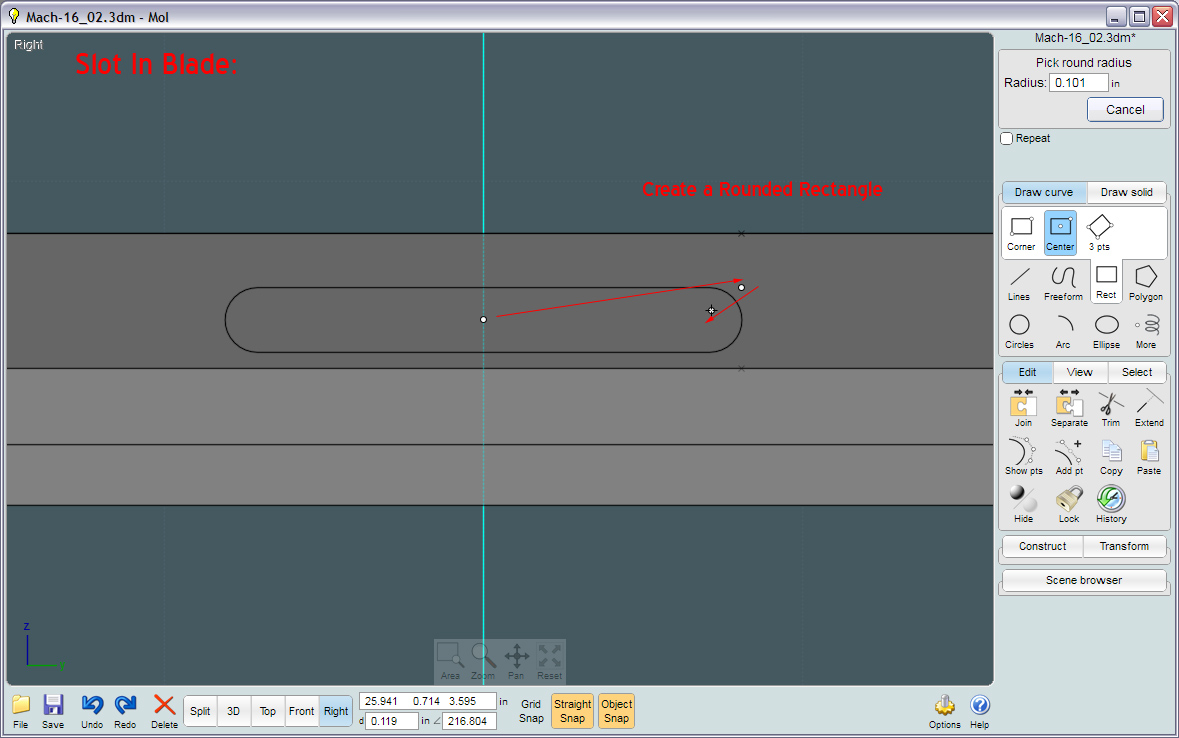

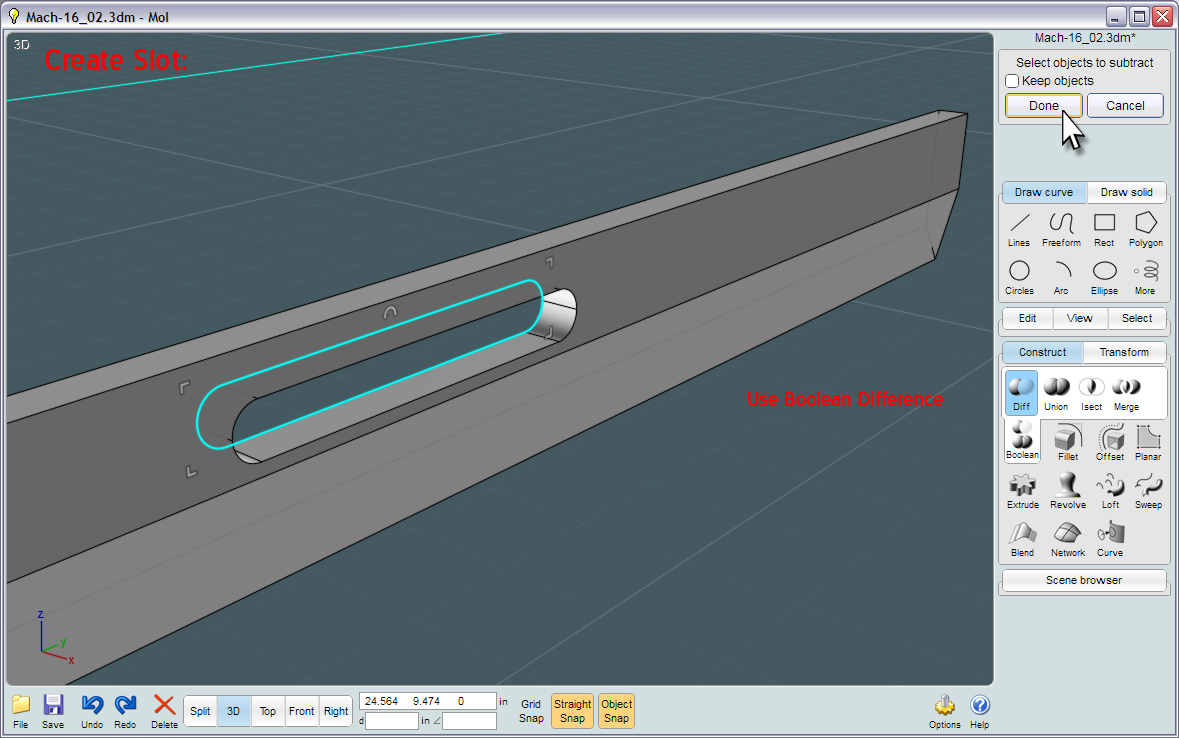

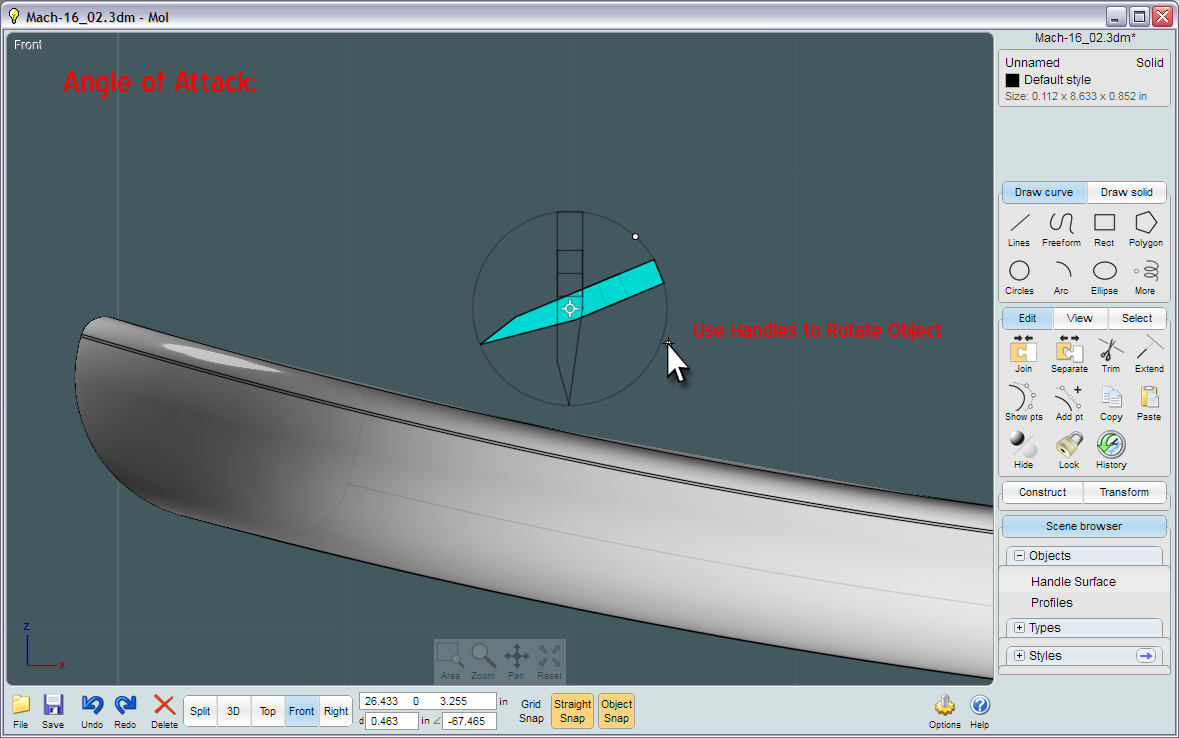

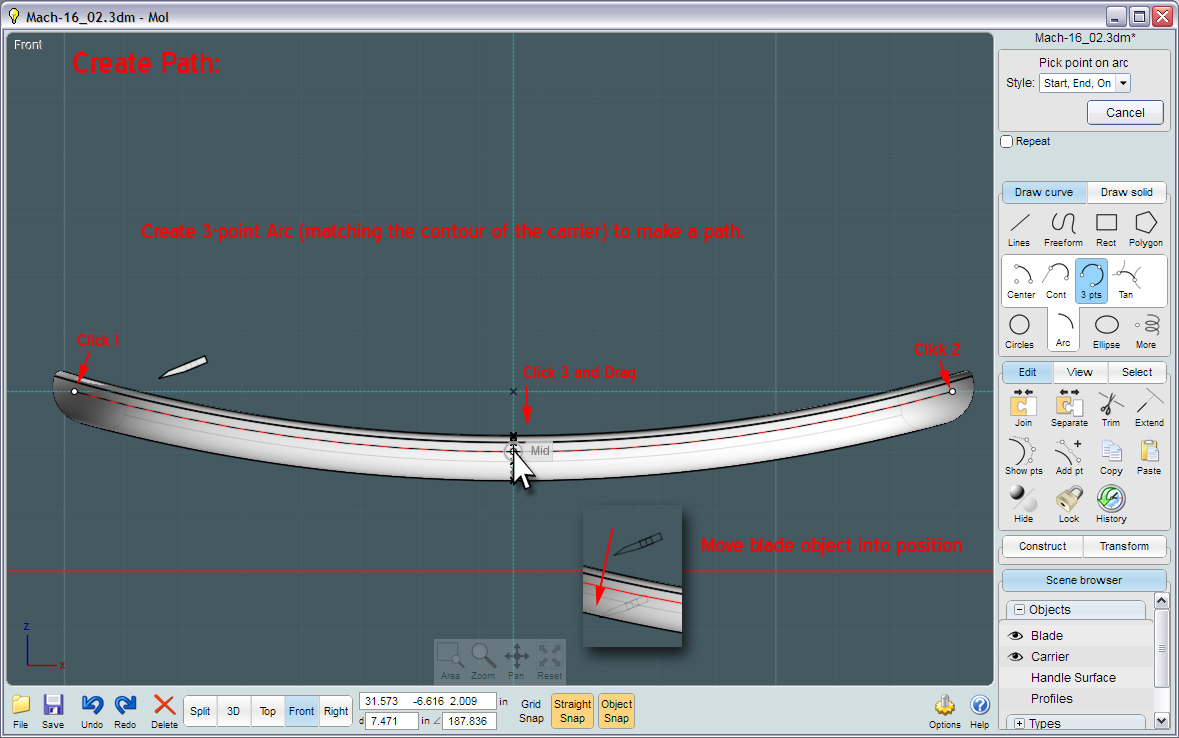

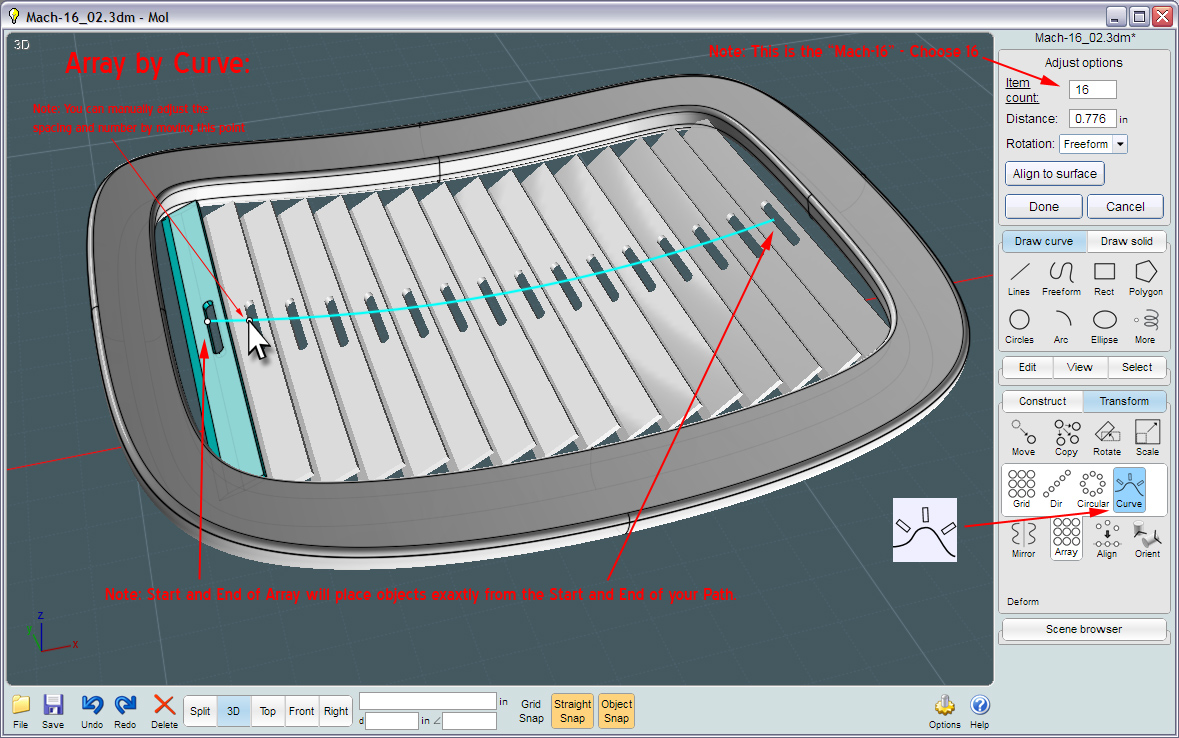

I provided the UI screen-captures along with notations:

This razor, of course is more styled like a women's wet razor due to it's organic handle.

The usefulness of this model is that is contains many common construction techniques for making so much else.

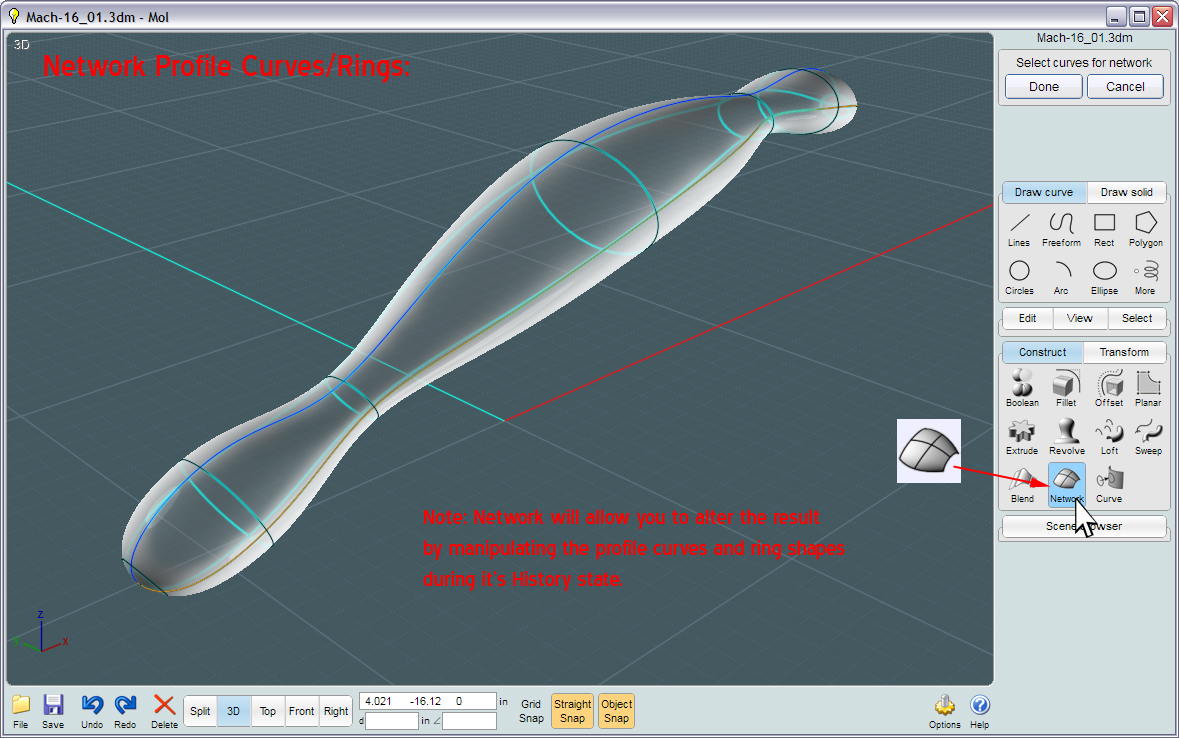

The main feature to the handle of this razor is what I coined an "Axial Network Surface", because this type of network is configured in a sleeve or tube-like arrangement.

See my tutorial on this type of network:

http://moi3d.com/forum/index.php?webtag=MOI&msg=4610.1

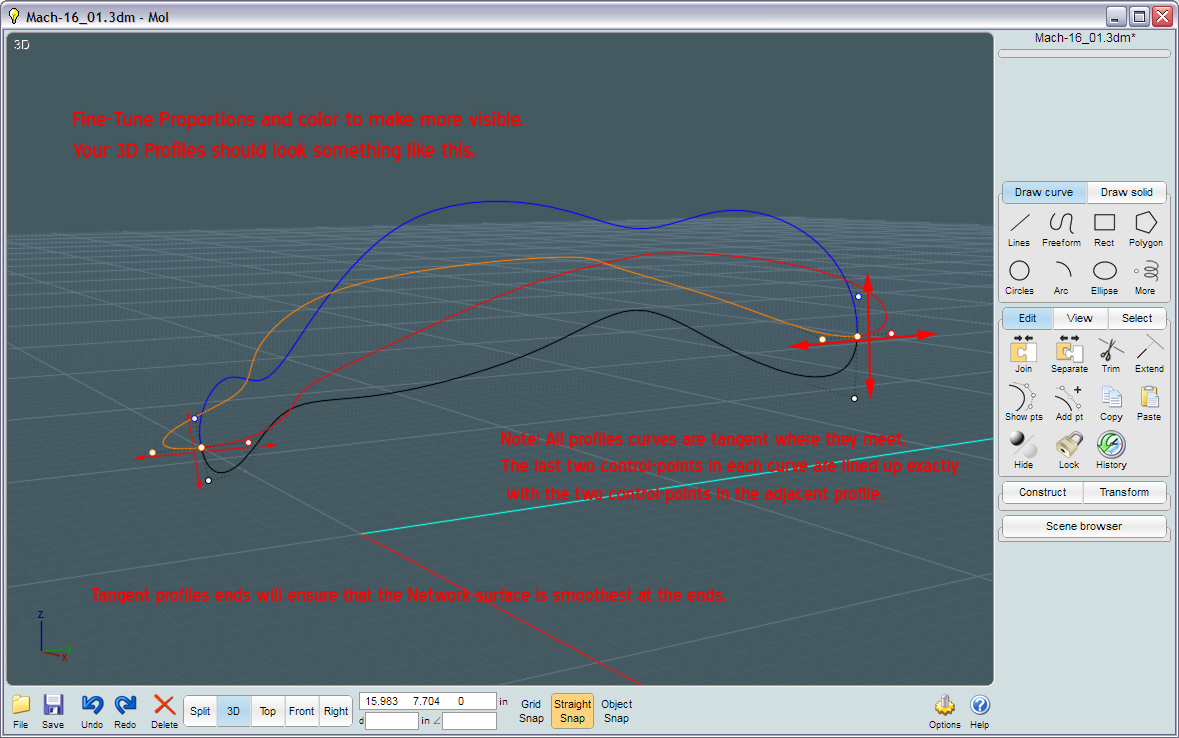

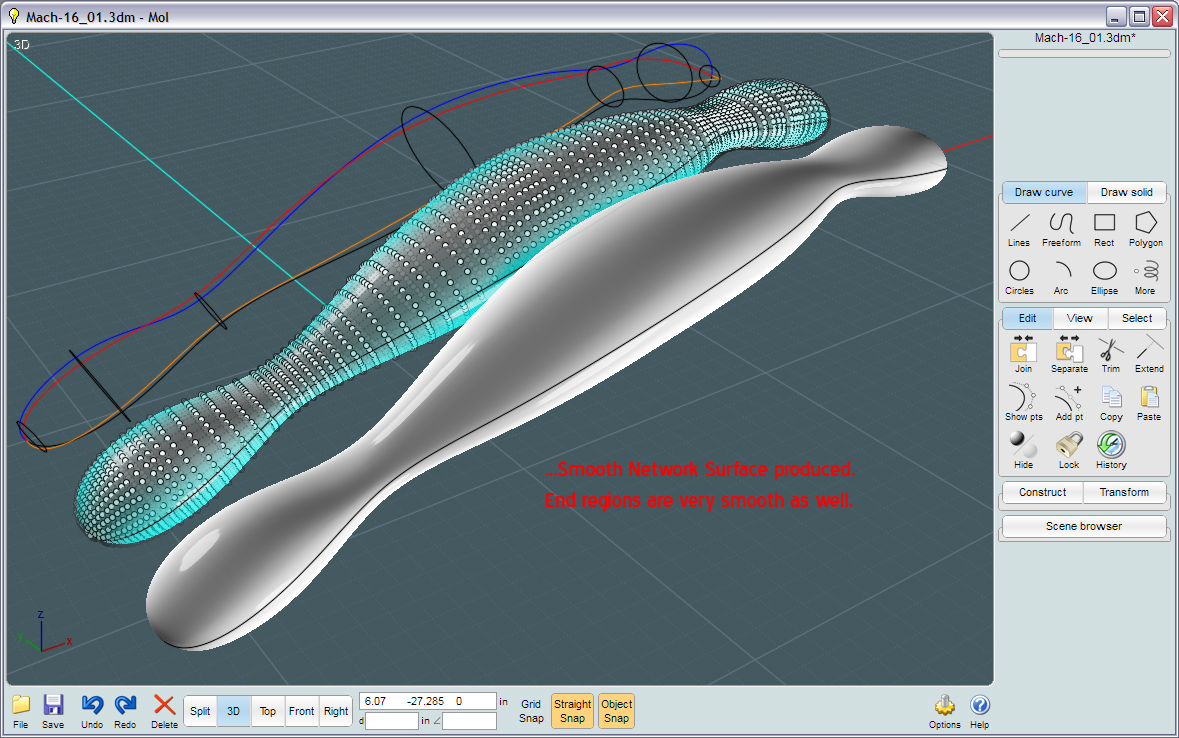

If you wish for your Axial Network to come to smooth ends (not pointy), if the profile curves that form them are tangent at their adjoining ends, then that end-area is most likely to appear smooth.

In the History state of the Network surface, you are allowed to manipulate the profile curves to fine-tune the general shape of the Network.

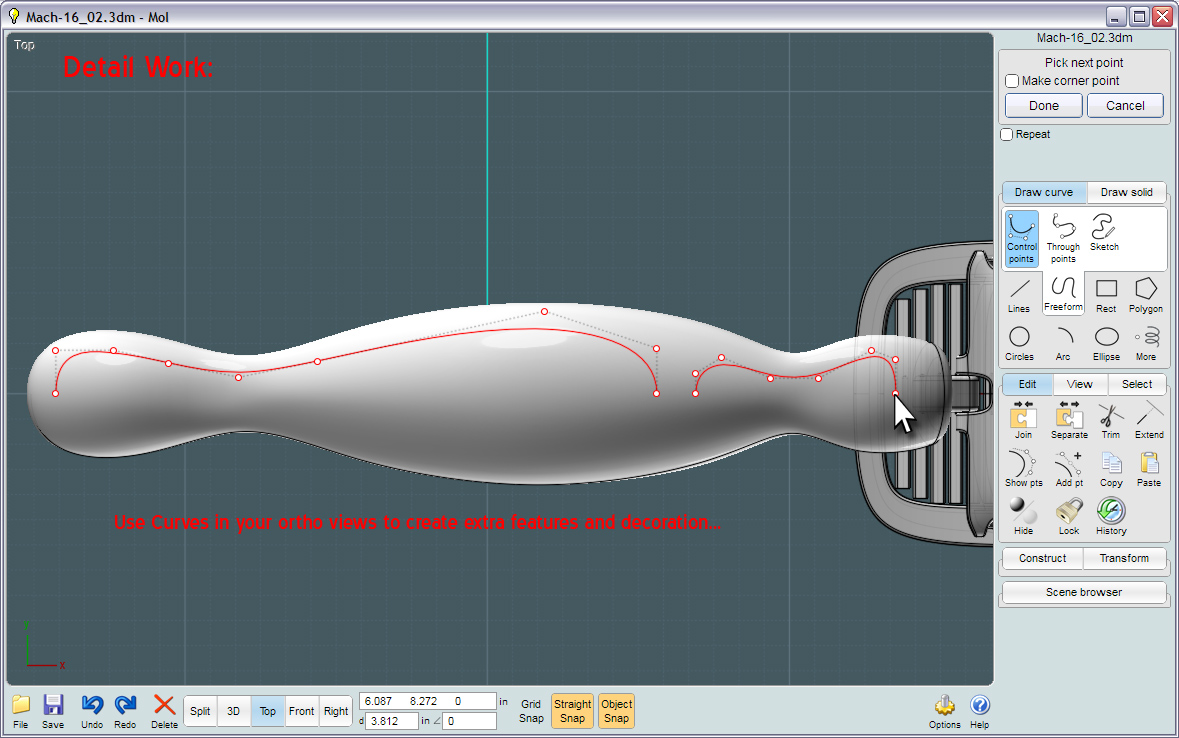

Using your "ortho", or side views to build the profile curves allows you to build 3D curves while only having to concentrate on its shape in one dimension at a time.

Moving the handle bars across the axis point, if the axis is switched to reside at the opposite end of your selected handle will provide and interactive mirror image of your object. Changing any aspect of the original object will affect this change in the "clone" while is it's History state.

The number of Profile Curves is not crucial, as long as there are at least two of them. Greater definition can be achieved by adding curves, and they don't have to reside in flat 2D planes.

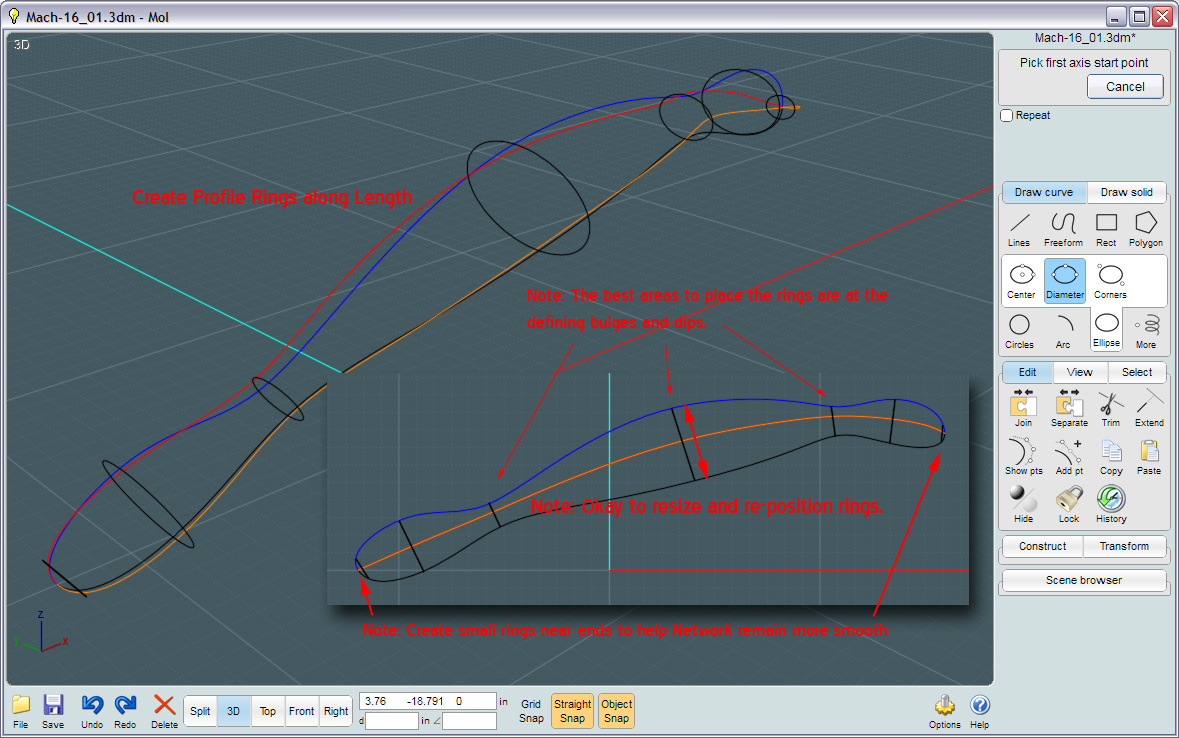

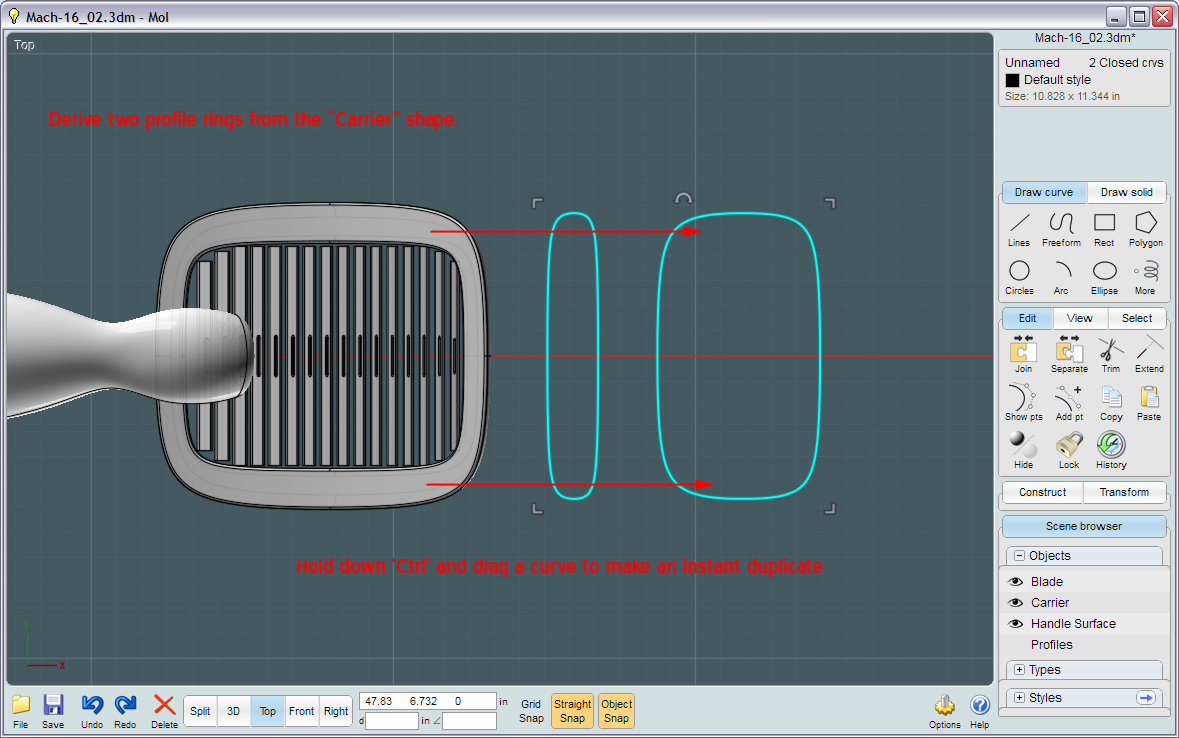

The "Rings" are closed curves that make this kind of Network surface "Axial". The seam (BRep) that is created is closed and will share the curve at both parts of the surface along the two matching edges. When you use un-closed curves, you get a Sheet-type Network.

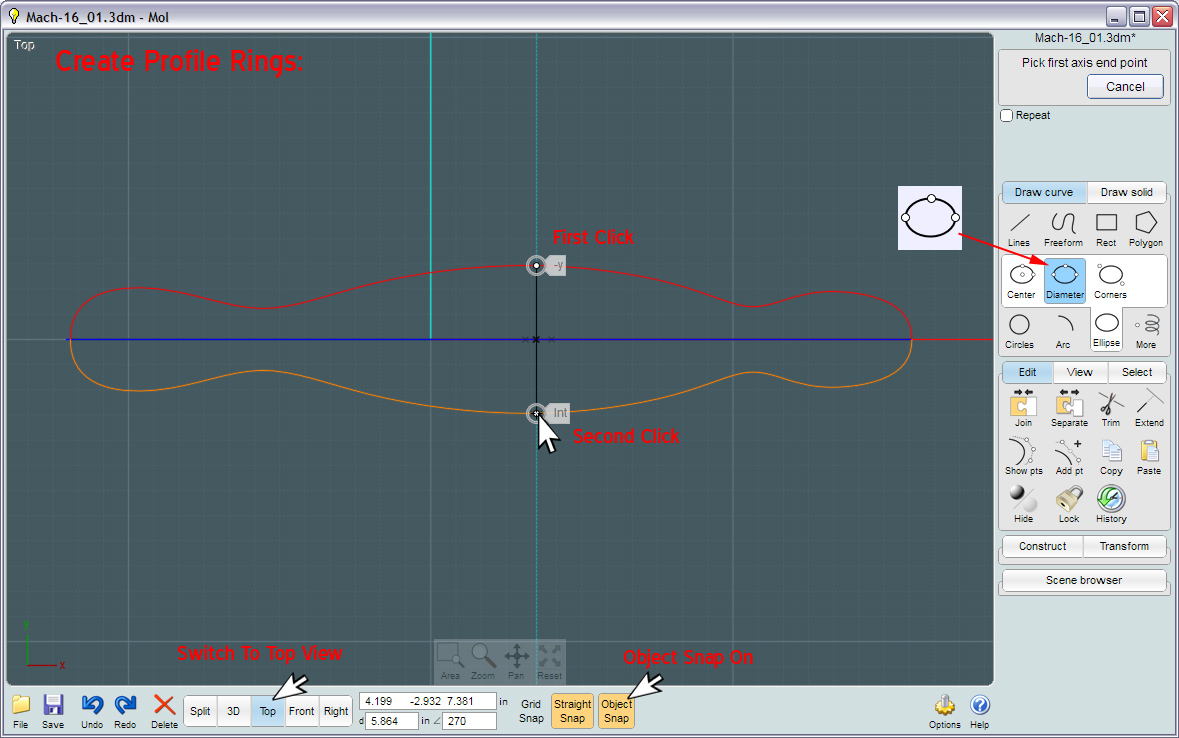

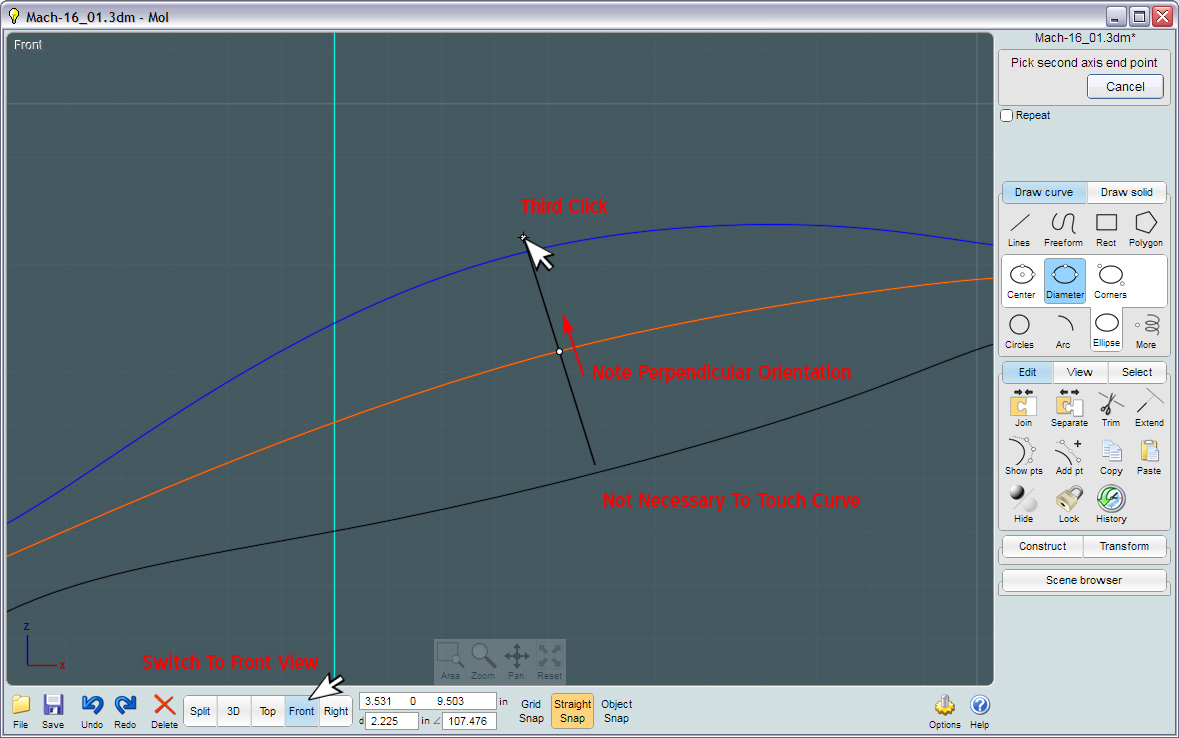

Using the 3-point Ellipse will let you build accurately-placed 3D rings while working in 2D ortho views.

These "Rings" do not have to touch the profile curves, just be near them. Network will average the result. However, accuracy helps.

You really only need one or two rings, but more will re-enforce the shape you desire.

Rings are placed near the ends for the profile curve junctions so that Network will see a smoother surface at that area.

If not, crumpling and overlapping may occur. Also, even if the Network surface is to have a non-circular shape to it, the end rings should still be circles.

The circles more define a unified occurrence of the surface as the lines try to meet.

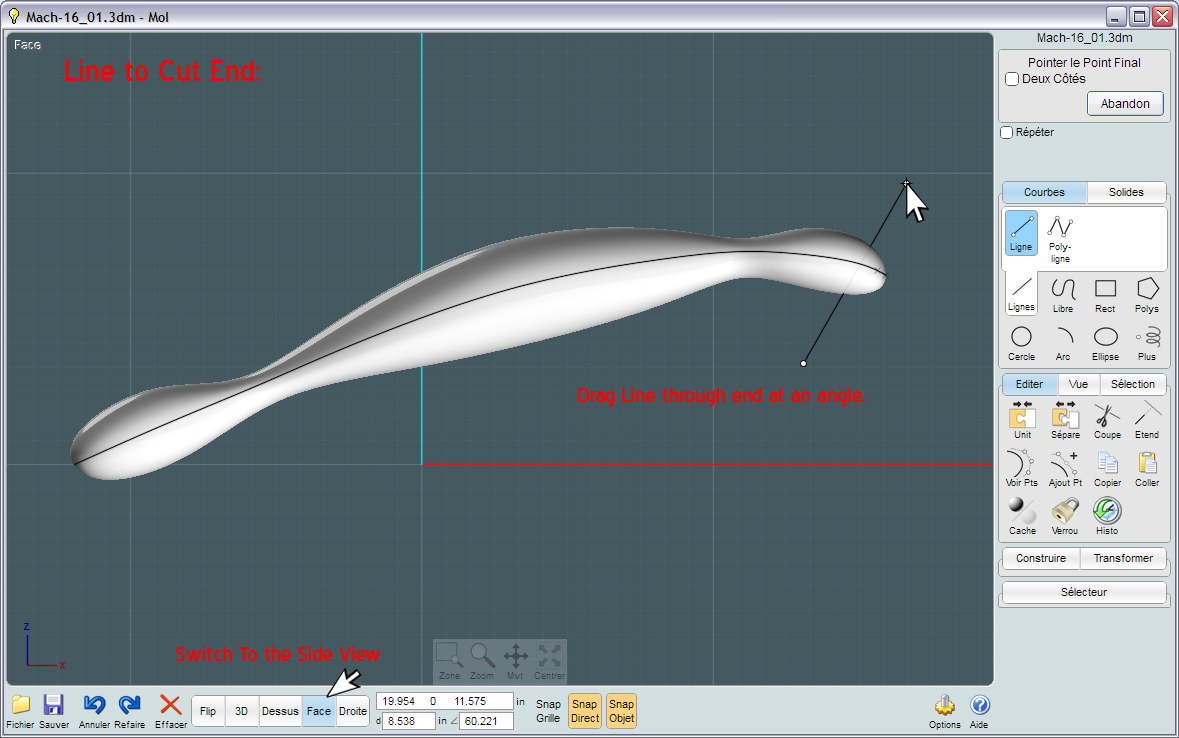

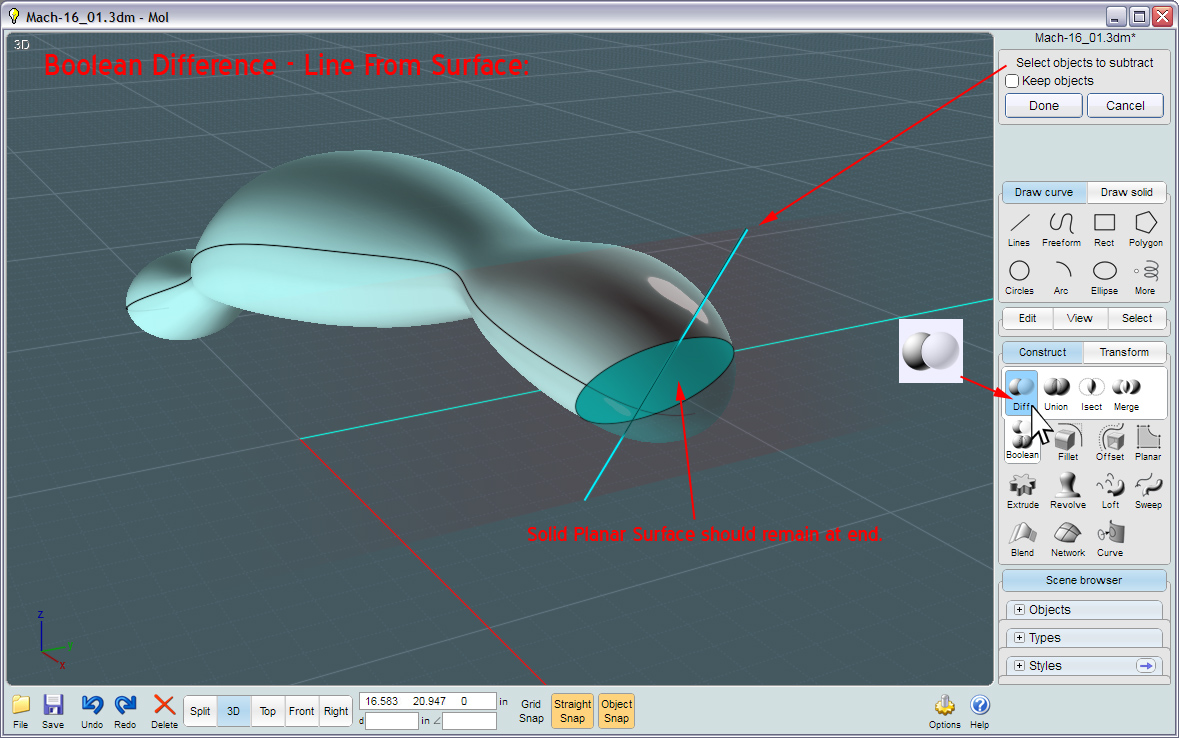

We need a more flat end to refine out shape. The beauty of Network surfaces is that you can continue to add or subtract to them to build more complex shapes.

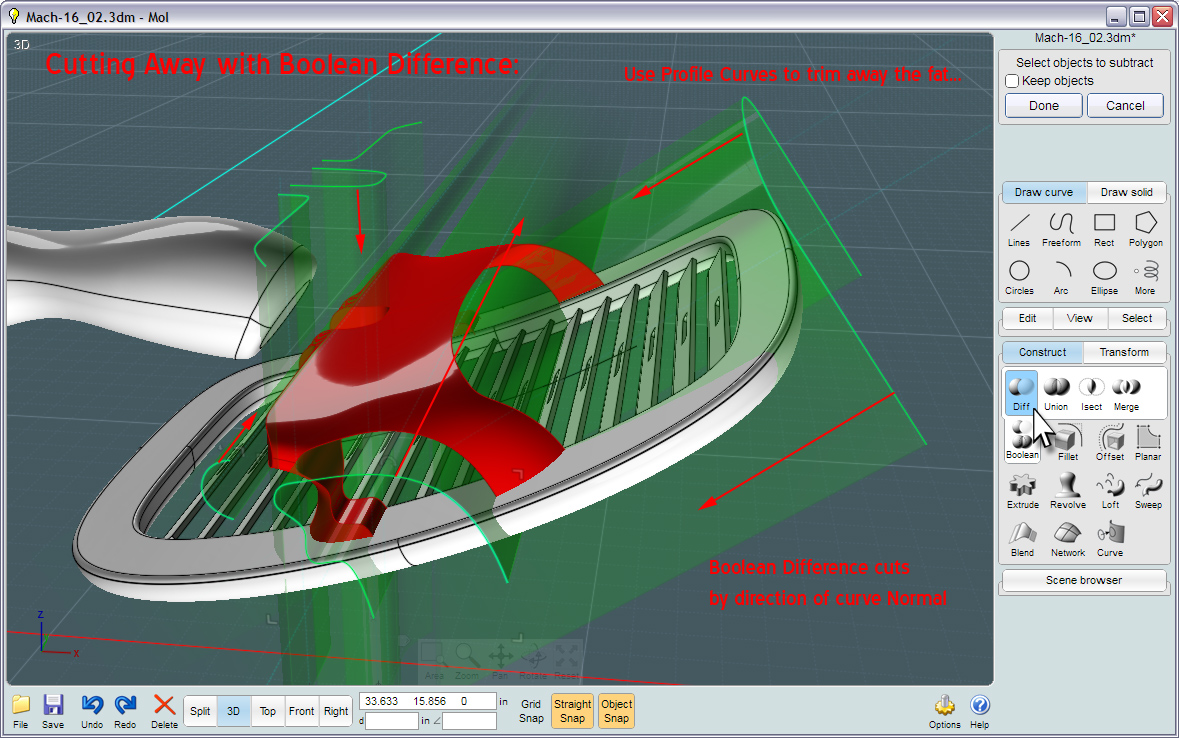

Boolean Difference will essentially "cut" or "Trim" your object by projecting an invisible extrusion of your cutting curve in the direction of the curve's normal (perpendicular to its planar orientation).

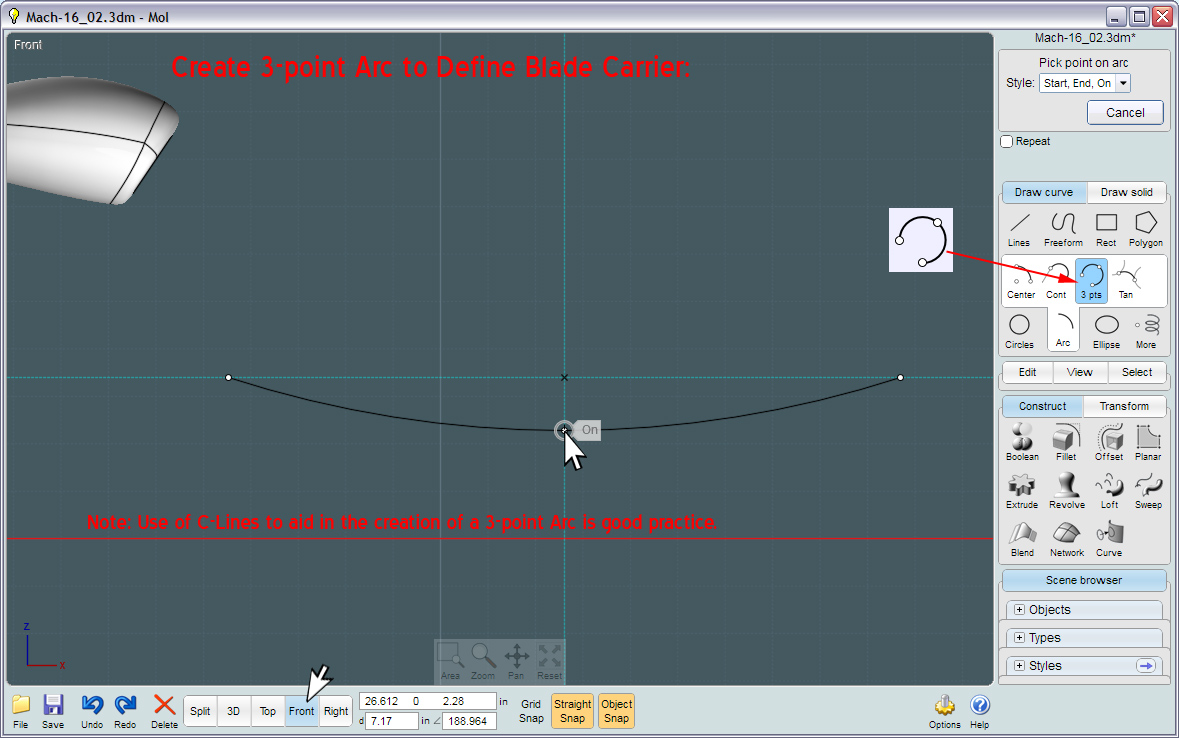

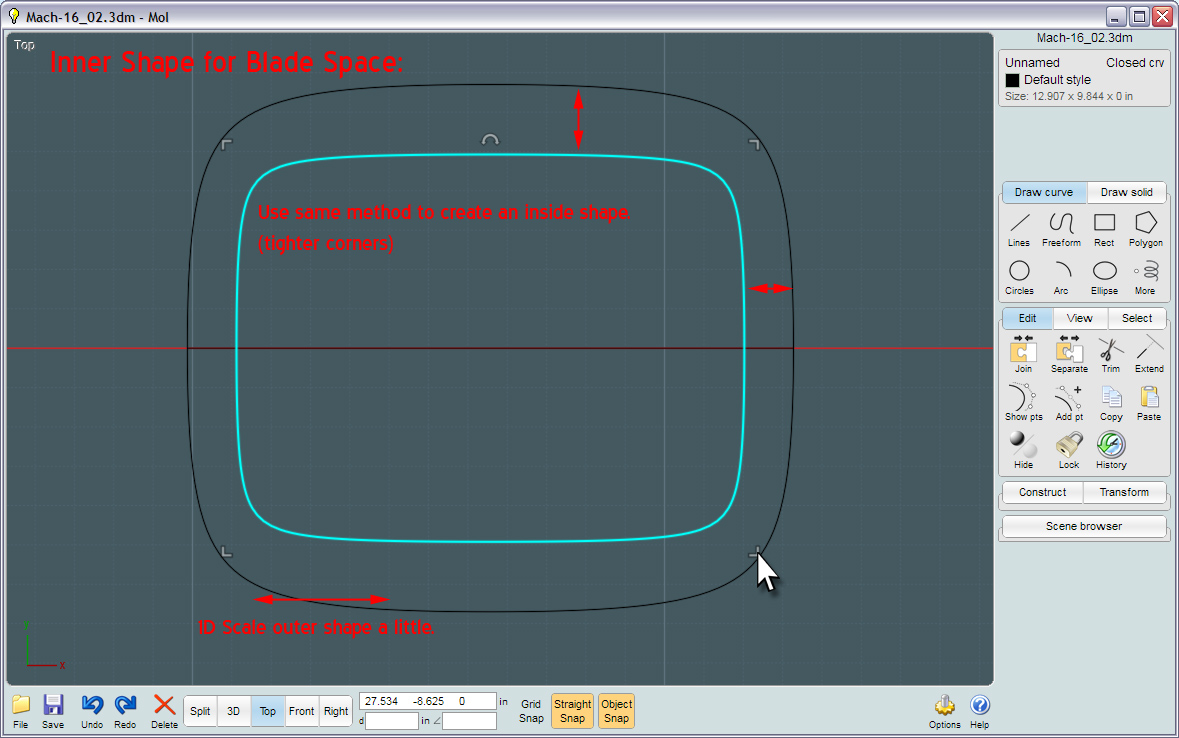

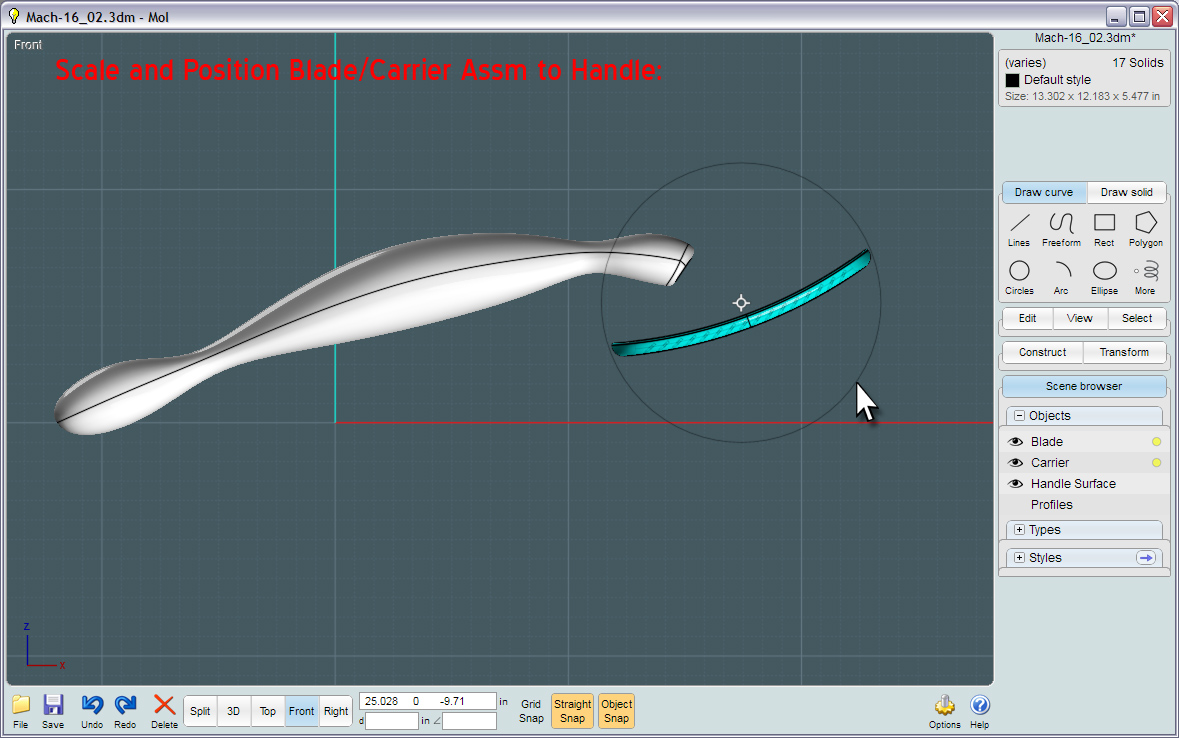

The razor blade carrier is curved, so we start with an Arc.

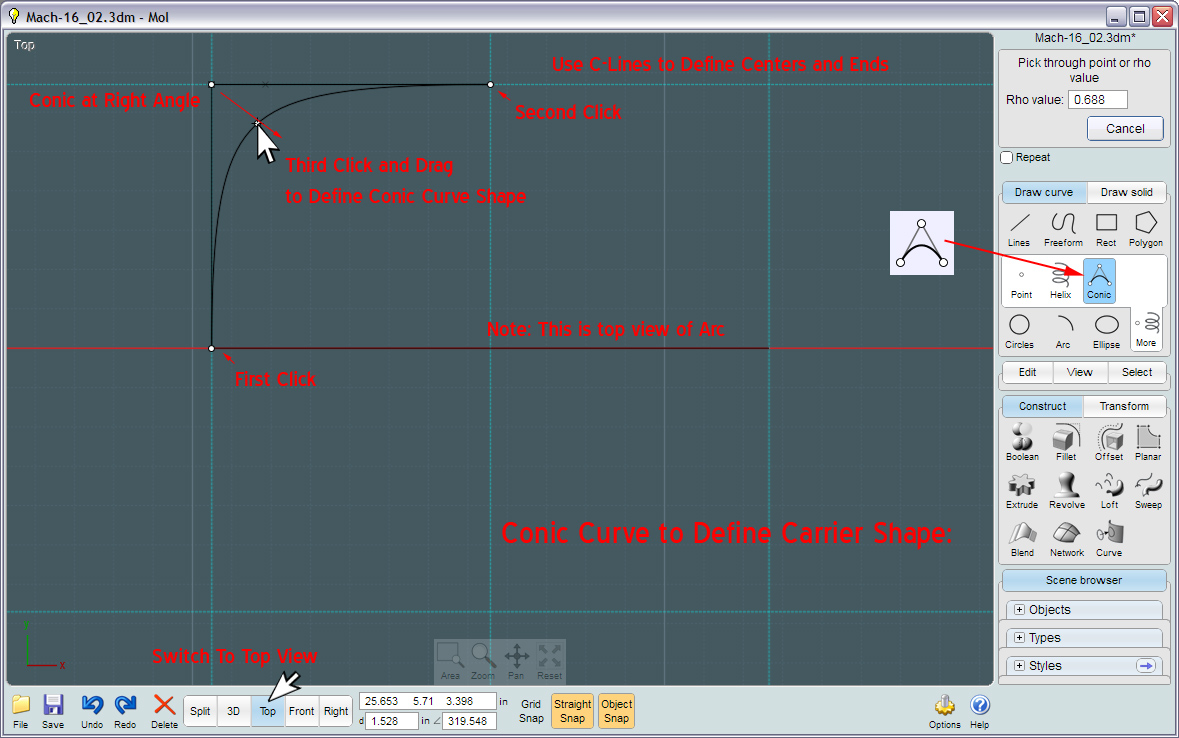

Switch to Top View... Here you see the Arc from the top.

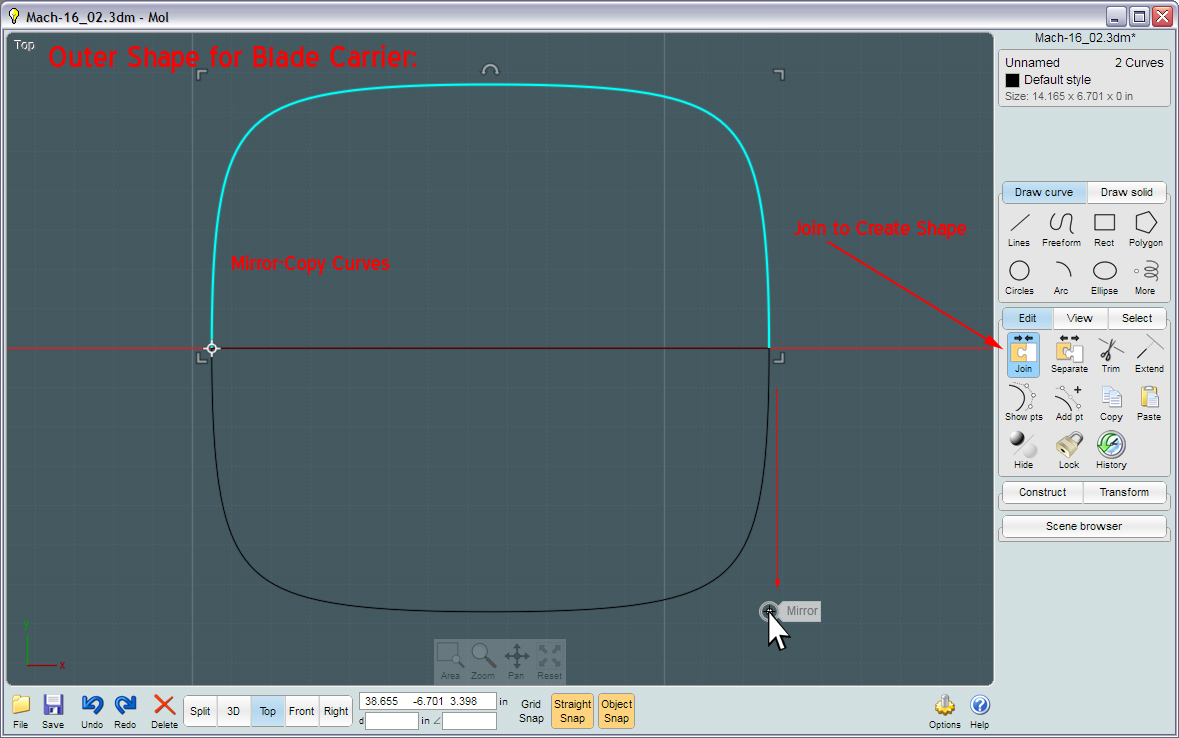

Conics produce a very nicely smoothed out box shape.

Make the inside as close to square as possible, as you'll have to have room for all those blades!

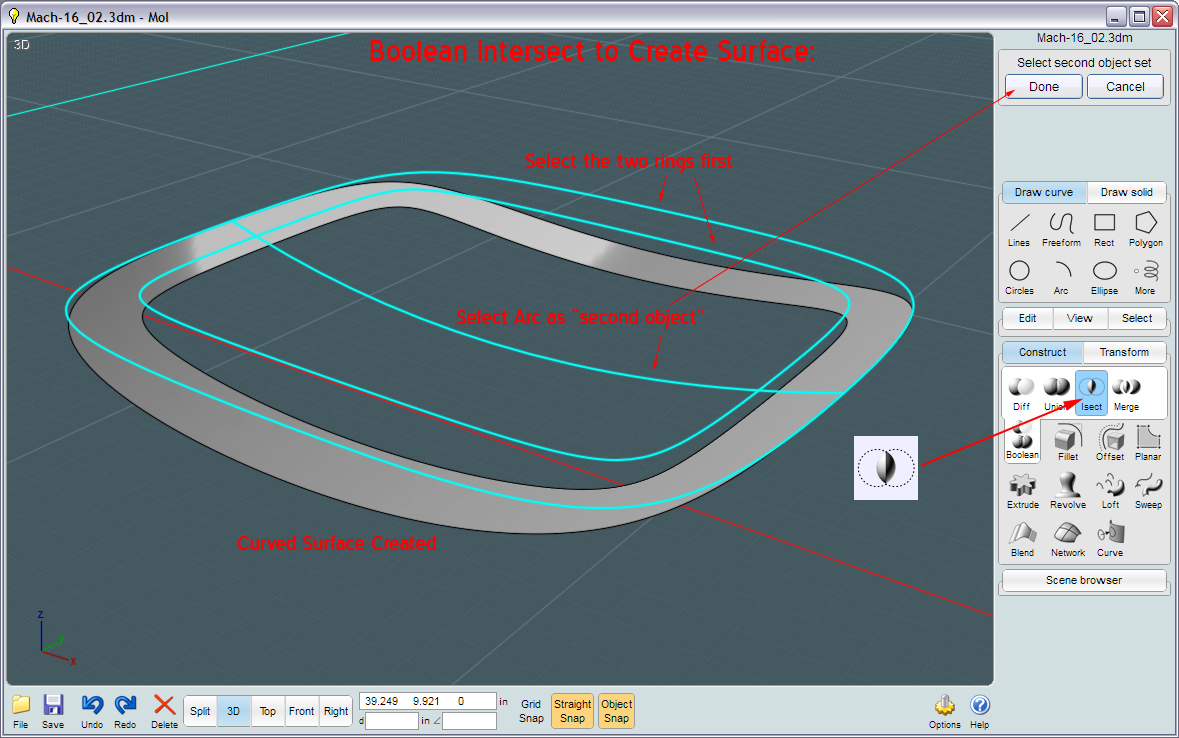

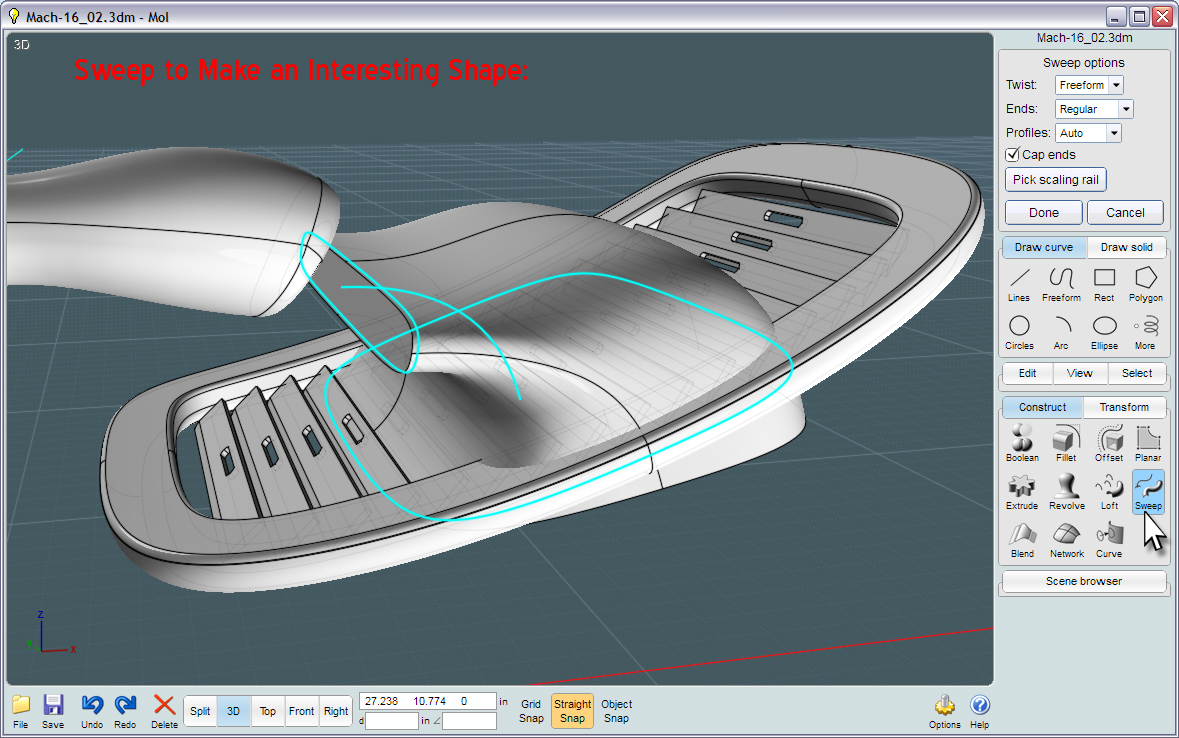

The magical Boolean-Intersect tool can take curves and objects and any combination and will produce a blending of the two.

Or in this case, it sees the arc and sees the shapes and knows to make the curved surface that matches the shapes.

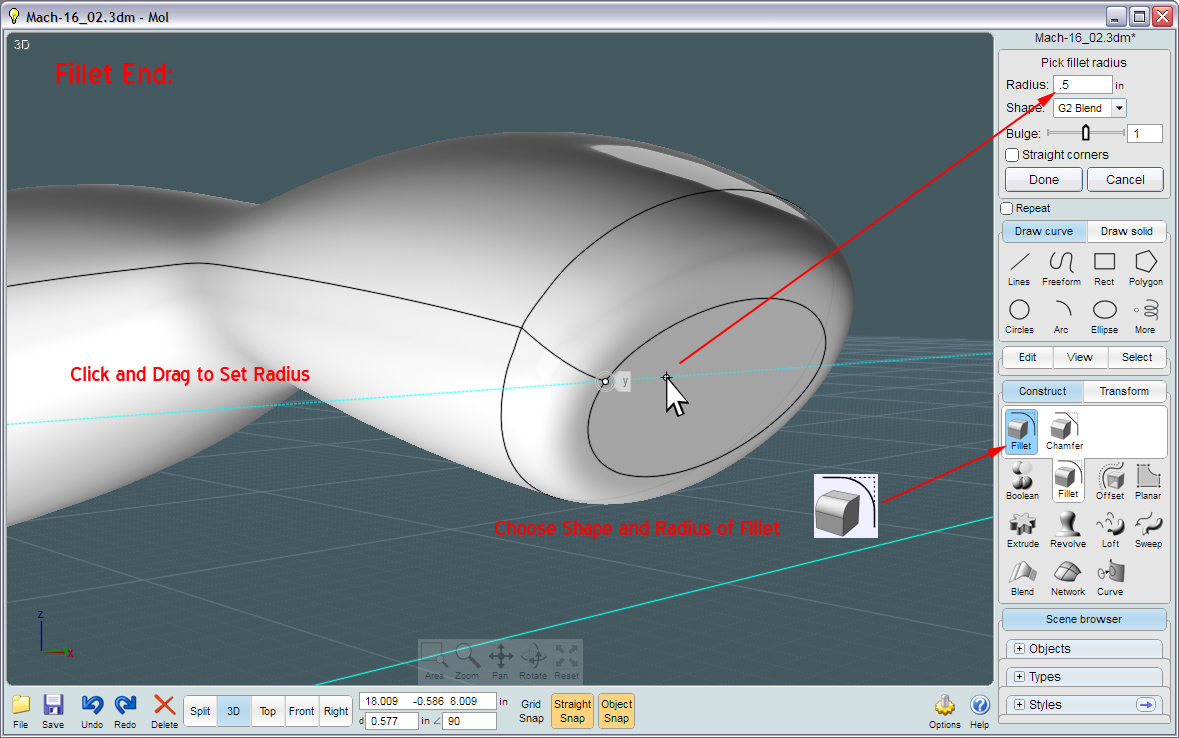

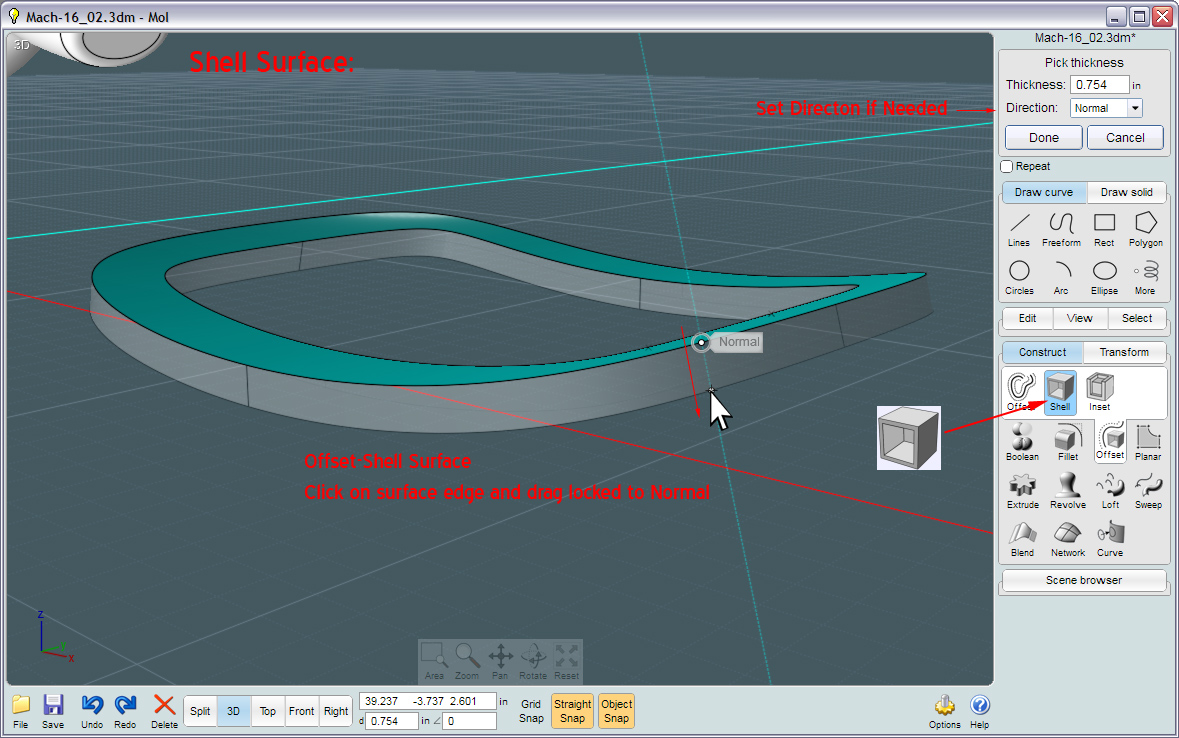

...An improvement on my original process. Using Offset-Shell will form a closed object thickness of the surface that is exact in angle and depth.

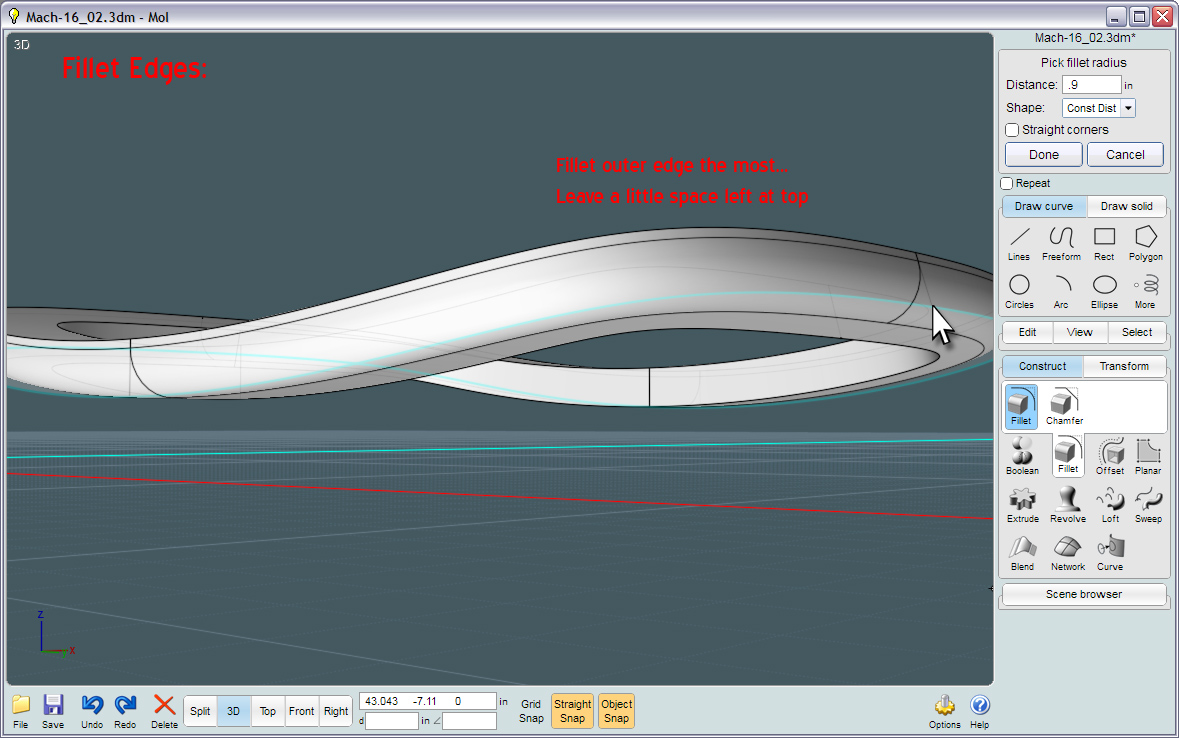

...This way, the Fillet is extremely accurate around the perimeter.

Time to make your high-tech poly-chromium drop-forged razor-blades.

(hmm.. Why are there holes in some blades?)

There is no way as of yet, to tell Array-by-Curve that you want the start and end objects to sit at exact locations.

So you have to remember to trim your path at those exact areas.

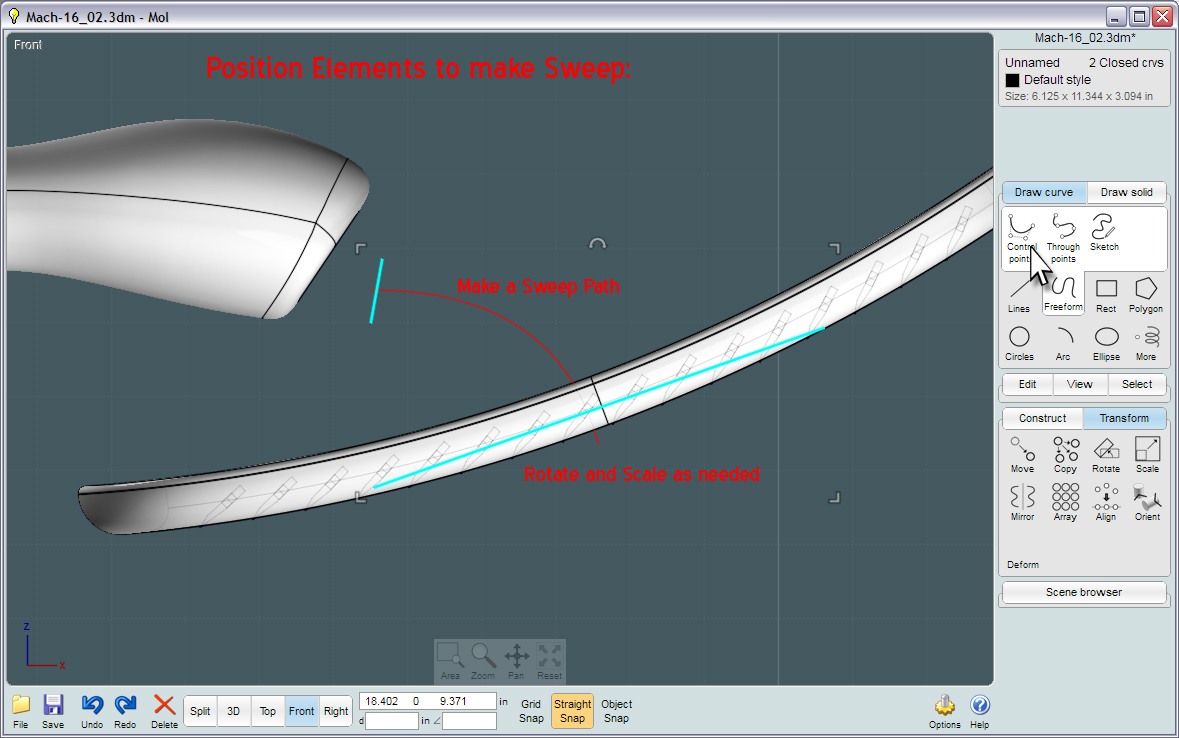

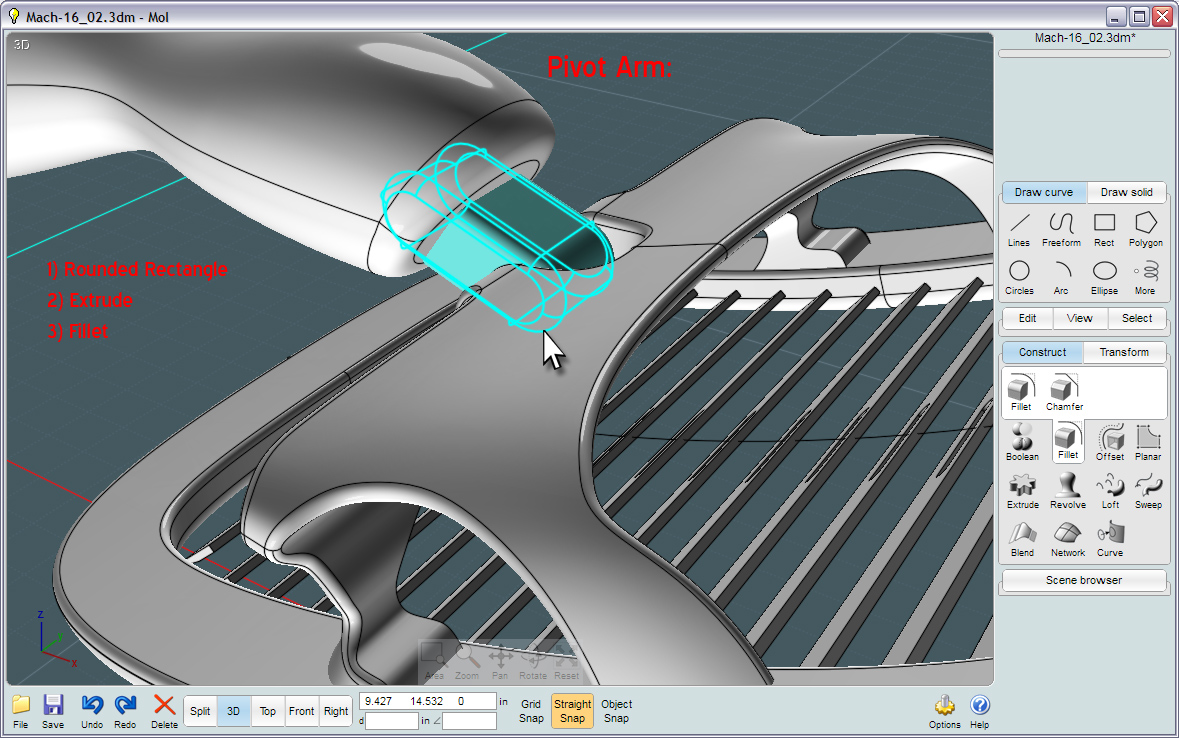

I needed to make a flexible bridge to hold the blade carrier. Here is how to make a very organic-looking version:

Using the original conic shaped rings gives you a smooth shape.

If this comes out funny, or has overlaps and creases, you'll need to both adjust the proportions of the rings and perhaps the Sweep-path shape.

...It's like cutting

digital butter with a NURBS butter knife!

In this operation, I create profiles in each ortho view to be essentially extruded through the Swept object leaving a strange shape with legs when finished.

Note that the Boolean-Difference cut direction is made in relation to cutting curve profile's direction. Or its follow-through angle matches the planar normal direction of the profile itself. ...In other words: if you angle a profile curve it will cut you object at that angle.

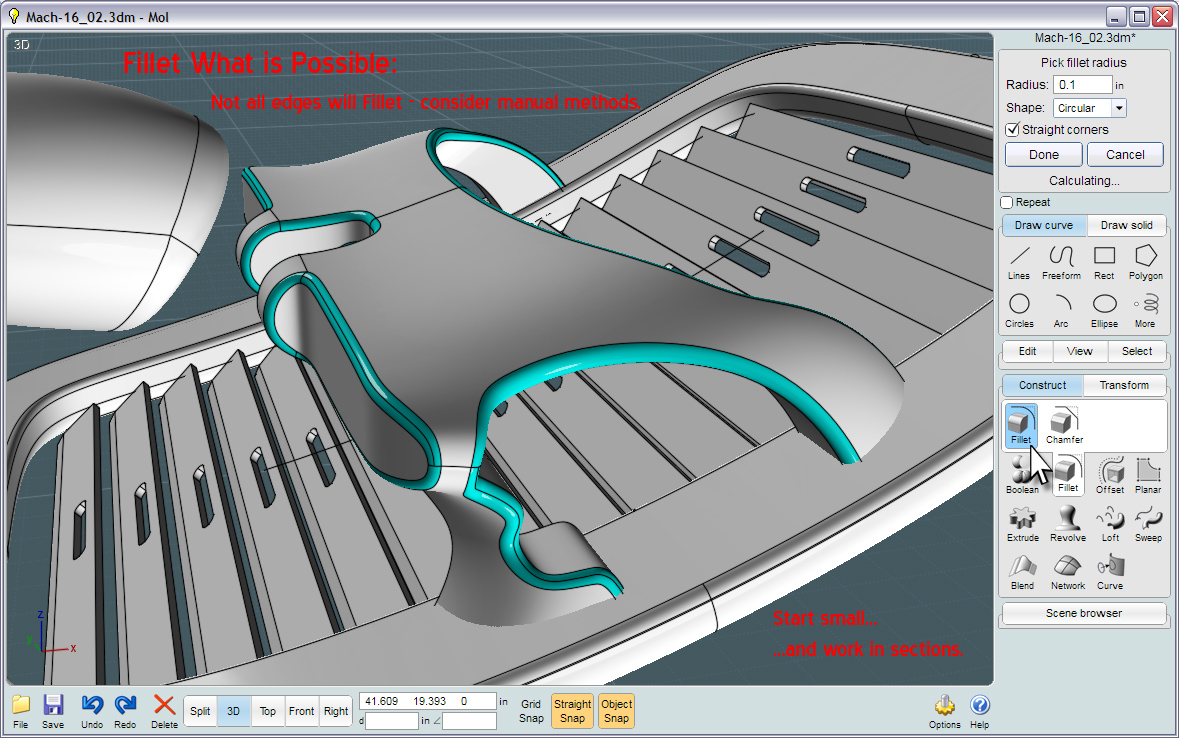

No, MoI's Fillet engine cannot handle every nook and cranny of any object you throw at it. It's worth a try though.

Start small and in local areas. If you absolutely have to have smoothed edges -

See my tutorial on making manually created Filleted edges using Sweep and Blend:

http://moi3d.com/forum/index.php?webtag=MOI&msg=4607.5

By this point - it is time to start using your new skills in MoI and come up with your own refinements.

Don't be afraid to try something daunting or difficult. You can only learn that way.

Flow is a great way to add detail to the handle. And adding little holes and extra "greebles" (or important looking and tiny features) to your models will make it appear more produced.

Hopefully I didn't leave anything out of this tutorial...

Have fun!